Features of rigid casters include:

- Fixed Direction: Rigid casters do not swivel or pivot like swivel casters. They are fixed in one direction, providing straight-line movement only. This design ensures stability and prevents the wheel from turning, making them ideal for applications where straight-line movement is required.

- Load Capacity: Rigid casters are often designed to have a higher load capacity compared to swivel casters. They are commonly used in applications where heavy loads need to be moved in a straight line, such as on carts or dollies.

- Simple Construction: Rigid casters typically have a simple construction with a wheel mounted on an axle or frame. This simplicity makes them durable and reliable for many industrial and commercial applications.

- Cost-Effective: Rigid casters are often more cost-effective than swivel casters because of their simpler design. This makes them a preferred choice when mobility in multiple directions is not required.

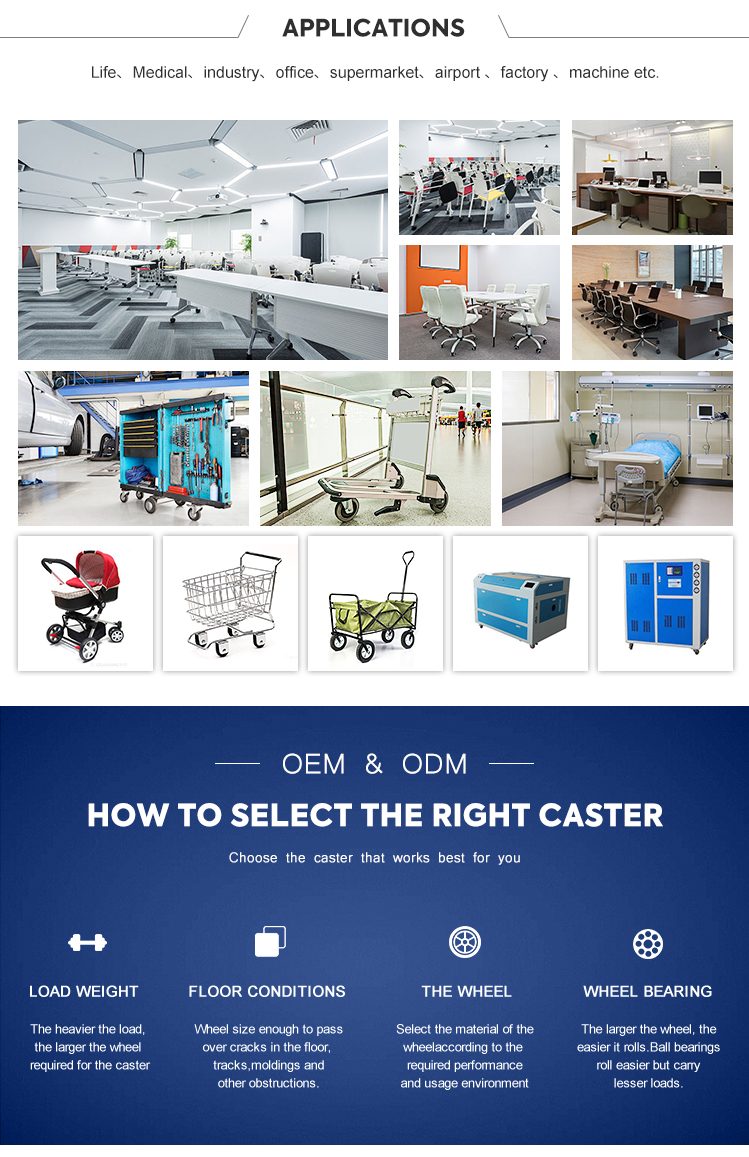

It’s important to choose the right type of caster based on your specific application requirements to ensure optimal performance and safety. Rigid casters are suitable for applications where you need to move heavy loads in a straight line without the need for frequent changes in direction.

Rigid casters offer several advantages, including:

- Directional Precision: Rigid casters offer precise directional control, which is crucial in applications where alignment and tracking are essential, such as conveyors, assembly lines, and industrial machinery.

- Reduced Wear and Tear: With fewer moving parts, rigid casters experience less wear and tear, leading to longer service life and reduced replacement costs.

- Low Maintenance: Because they lack the swiveling mechanism found in swivel casters, rigid casters require less maintenance and are less prone to mechanical issues.

- Braking Options: Many rigid casters come with built-in brakes or can be equipped with brakes to provide extra control and safety when needed.

It’s important to select the right type of caster based on your application’s requirements and environment. Rigid casters are advantageous when you need stability and straight-line movement, but they are not suitable for applications where frequent changes in direction are necessary.

Customizable aspects of rigid casters include:

- Wheel Material: Rigid casters can be fitted with various wheel materials based on the application’s needs. Common wheel materials include hard rubber, polyurethane, steel, phenolic, and more. Each material has different properties such as load capacity, durability, and resistance to various conditions.

- Wheel Diameter: The size of the caster wheel can be customized to match the load capacity and terrain. Larger wheels are suitable for heavier loads and rough surfaces, while smaller wheels are used for lighter loads and smooth floors.

- Load Capacity: Rigid casters are available in different load capacity ratings, allowing you to select casters that can handle the specific weight requirements of your application.

- Mounting Style: Rigid casters can be mounted using different methods, including plate mounting and bolt hole mounting. The choice of mounting style depends on your equipment and installation needs.

- Brake Options: Rigid casters can be customized with various braking mechanisms to provide additional control and safety. Options include wheel brakes, total lock brakes, and directional locks.

- Bearings: The type of bearing used in the caster wheel can be customized. Common options include ball bearings, roller bearings, and precision bearings, each with different characteristics related to rolling resistance and load capacity.

Customizing rigid casters allows you to optimize their performance and suitability for your specific application, ensuring that they meet your exact requirements in terms of load capacity, mobility, and environmental factors.

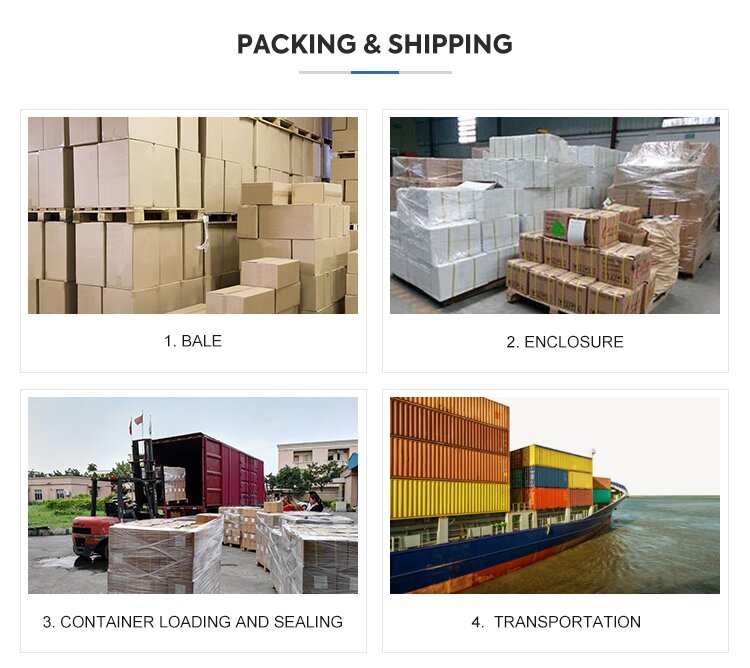

There are several packaging solutions available for rigid casters, including:

- Bulk Packaging: Rigid casters may be packaged in bulk quantities, typically in boxes or crates, for industrial and commercial applications where large quantities of casters are needed. This type of packaging is often used for OEM (Original Equipment Manufacturer) customers.

- Individual Packaging: For smaller quantities or retail sales, rigid casters can be individually packaged in clear plastic or cardboard boxes. This packaging allows customers to easily see the product and provides protection during shipping and storage.

- Blister Packaging: Blister packaging involves placing rigid casters on a plastic or cardboard backing with a clear plastic blister covering them. This packaging method provides visibility and protection, making it suitable for retail display.

- Hang Tags: Some rigid casters come with hang tags that allow them to be hung on display hooks in retail settings. Hang tags often provide product information, specifications, and branding.

- Custom Packaging: Depending on the customer’s requirements and branding, manufacturers may offer custom packaging solutions that include logos, labels, or printed product information. This is common for casters used in specialized or high-end equipment.

- Protective Wrapping: Rigid casters, especially those with sensitive or delicate wheel materials, may be individually wrapped in foam or plastic to protect them from scratches or damage during shipping and storage.

The choice of packaging solution depends on factors such as the type of caster, the quantity ordered, the distribution channels, and customer preferences. Packaging is an important consideration to ensure that rigid casters arrive in good condition, are easy to handle, and can be readily identified by customers or assembly personnel.