Features of spring-loaded casters include:

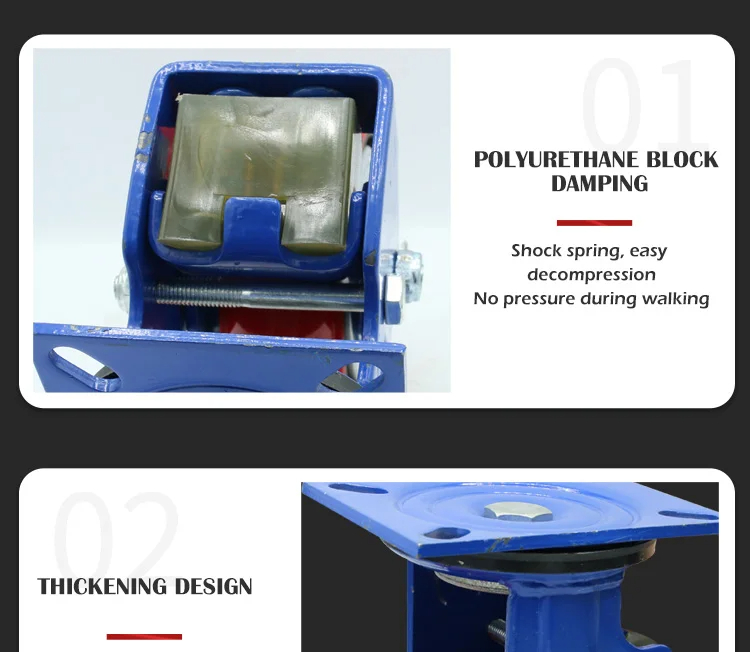

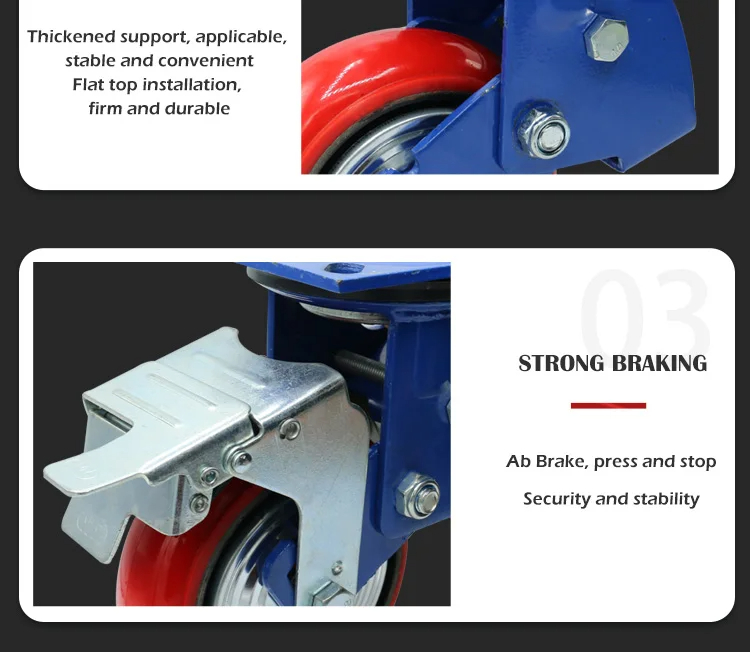

- Shock Absorption: Spring-loaded casters are designed to absorb shock and vibration. They can effectively cushion and protect delicate or sensitive cargo from damage during transportation.

- Reduced Noise: These casters often operate quietly due to their shock-absorbing properties. This feature is particularly valuable in environments where noise reduction is essential.

- Enhanced Floor Protection: Spring-loaded casters are gentle on floors, reducing the risk of floor damage, such as scuffs and scratches. They are suitable for use on a variety of floor surfaces, including hardwood, tile, and linoleum.

- Improved Ergonomics: Spring-loaded casters can provide a smoother and more controlled ride, making it easier for operators to push or pull carts or equipment, reducing strain and fatigue.

In summary, spring-loaded casters are a valuable choice when you need to protect delicate cargo, reduce noise, and enhance the ergonomics of material handling equipment. Their shock-absorbing and floor-protecting features make them suitable for a wide range of applications in various industries.

Spring-loaded casters offer several advantages, including:

- Versatility: They can be used in a wide range of applications, including medical equipment, audio-visual carts, electronic devices, and other situations where shock absorption and floor protection are essential.

- Adjustable Load Height: Some spring-loaded casters offer height adjustment options, allowing users to adapt the caster height to specific load requirements or different surfaces.

- Vibration Dampening: Spring-loaded casters are effective at minimizing vibrations, which is crucial for the safe transport of sensitive equipment or materials.

- Weight Capacity: These casters are available in various weight capacities to accommodate different load requirements, ranging from light-duty to heavy-duty applications.

In summary, spring-loaded casters are a valuable choice when you need to protect sensitive cargo, minimize noise, and enhance the ergonomics of material handling equipment. Their shock-absorbing and floor-protecting features make them a versatile and practical solution for a wide range of applications in various industries.

Customizable aspects of spring-loaded casters include:

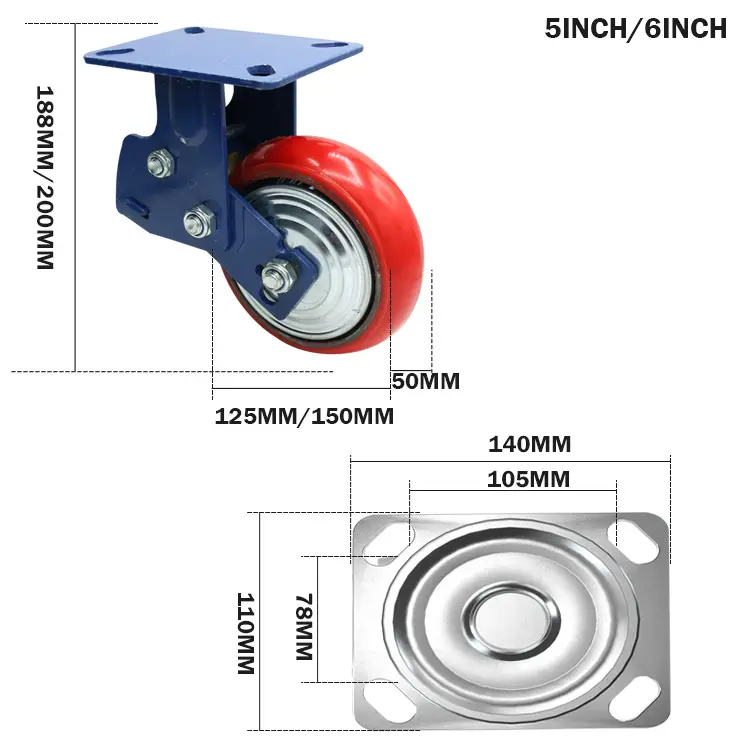

- Load Capacity: Spring-loaded casters can be customized to accommodate varying load capacities. Manufacturers can adjust the spring and caster components to ensure that the caster can effectively support the specific weight requirements of the application.

- Spring Stiffness: The stiffness of the spring in a spring-loaded caster can be customized to provide the desired level of shock absorption and load support. Different springs can be selected or designed to meet specific performance criteria.

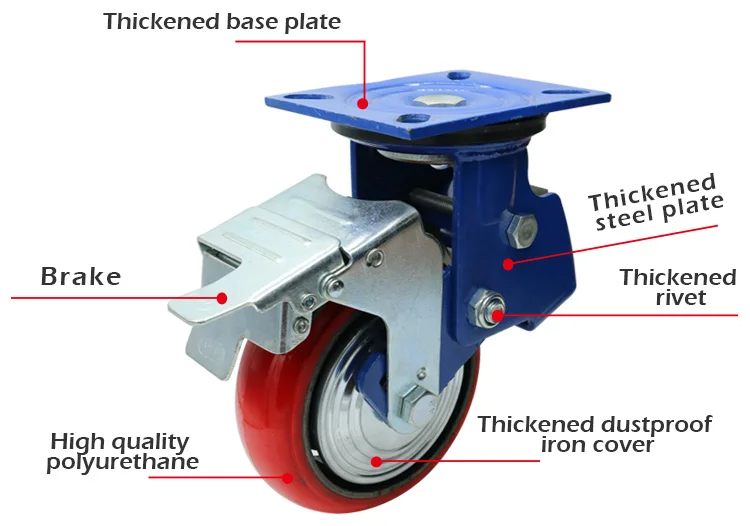

- Mounting Plate or Bracket: The mounting plate or bracket that attaches the caster to the equipment can be customized to fit the mounting hole pattern or size of the application. This ensures a secure and proper fit.

- Wheel Material: The material of the caster wheel can be customized to suit the specific environment. Different materials like rubber, polyurethane, nylon, or other compounds can be chosen based on factors such as floor type, temperature, and load requirements.

It’s essential to work with the manufacturer or supplier to discuss your specific needs and requirements when customizing spring-loaded casters for your application. They can provide guidance and ensure that the casters meet your unique specifications and performance expectations.

There are several packaging solutions available for spring-loaded casters , including:

- Individual Packaging: Each caster is individually packed in a protective cover or sleeve. This packaging method is ideal for ensuring that casters are kept separate and protected from scratches and damage during transport. It also allows for easy identification and handling.

- Bulk Packaging: Spring-loaded casters can be packaged in bulk, typically in quantities such as boxes or crates. They are often secured together to prevent shifting or damage. Bulk packaging is efficient when you need to transport a large number of casters for a project.

- Palletized Packaging: For larger quantities of spring-loaded casters, they can be placed on pallets, usually with a protective wrap or shrink wrap to secure them in place. Palletized packaging facilitates easy handling with forklifts or pallet jacks, making it suitable for bulk orders.

- Custom Packaging: Some manufacturers or suppliers offer custom packaging solutions tailored to the specific requirements of the application. This can include designing custom inserts, partitions, or protective materials to ensure the casters are snugly secured and well-protected during transit.

The choice of packaging solution often depends on the quantity of casters, their size, the shipping method, and the level of protection required. When purchasing spring-loaded casters, it’s essential to discuss packaging options with the manufacturer or supplier to ensure the casters arrive in the best condition for your specific application.