Features of heavy duty casters include:

- High Load Capacity: Heavy-duty casters are designed to bear substantial weight loads. They can typically support thousands of pounds, making them suitable for use in industrial, manufacturing, and commercial settings where large and heavy objects need to be moved.

- Durable Construction: Heavy-duty casters are built to withstand tough conditions and frequent use. They are often made from robust materials such as steel, forged steel, or high-strength alloys, ensuring longevity and resistance to wear and tear.

- Large Wheel Diameter: The wheels of heavy-duty casters are generally larger in diameter compared to standard casters. This larger size allows for more even weight distribution, smoother rolling, and enhanced stability.

- Swivel Locks: Many heavy-duty casters feature swivel locks, which allow you to immobilize the caster and prevent unwanted movement. This feature is essential when you need stability for tasks such as loading and unloading heavy objects.

In summary, heavy-duty casters are characterized by their ability to support heavy loads, durable construction, large wheel diameter, and a range of features that cater to the specific needs of industrial and commercial applications. These casters play a crucial role in ensuring the safe and efficient movement of heavy objects in various work environments.

Heavy duty casters offer several advantages, including:

- Versatility: Heavy-duty casters come in various configurations, including fixed, swivel, and swivel with brakes, providing flexibility for different applications. This versatility allows for easy customization to meet specific requirements.

- Shock Absorption: Some heavy-duty casters are equipped with shock-absorbing features, such as spring-loaded or pneumatic wheels. These features help protect both the caster and the transported goods from impact and vibrations.

- Floor Protection: Heavy-duty casters are available with different wheel materials, such as polyurethane or rubber, which offer superior grip and protect floors from damage. This is especially important when dealing with delicate or expensive flooring materials.

- Noise Reduction: Many heavy-duty casters are designed for quiet operation. They incorporate noise-reducing features to minimize workplace disruptions, making them suitable for use in quiet or noise-sensitive environments.

In summary, heavy-duty casters are essential for industries and applications where the reliable movement of heavy loads is a daily requirement. Their advantages, including high load capacity, durability, stability, maneuverability, and floor protection, contribute to improved efficiency and safety in the workplace. These casters offer an excellent solution for businesses and organizations that rely on the transportation of heavy equipment and materials.

Customizable aspects of heavy duty casters include:

- Wheel Material: Casters can be fitted with different wheel materials to suit specific floor surfaces and load requirements. Common options include polyurethane, rubber, nylon, and steel. The choice of wheel material influences factors such as grip, shock absorption, floor protection, and noise level.

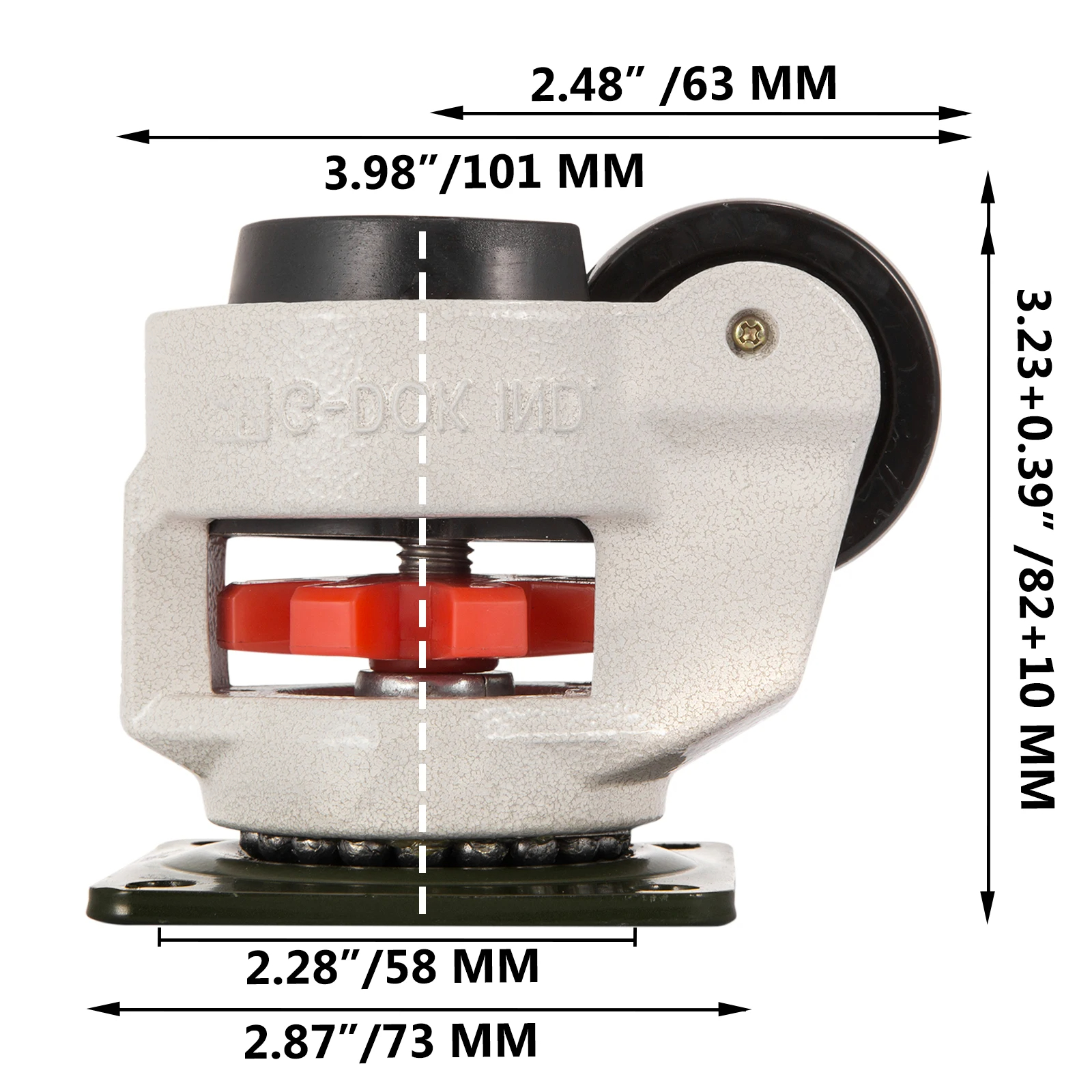

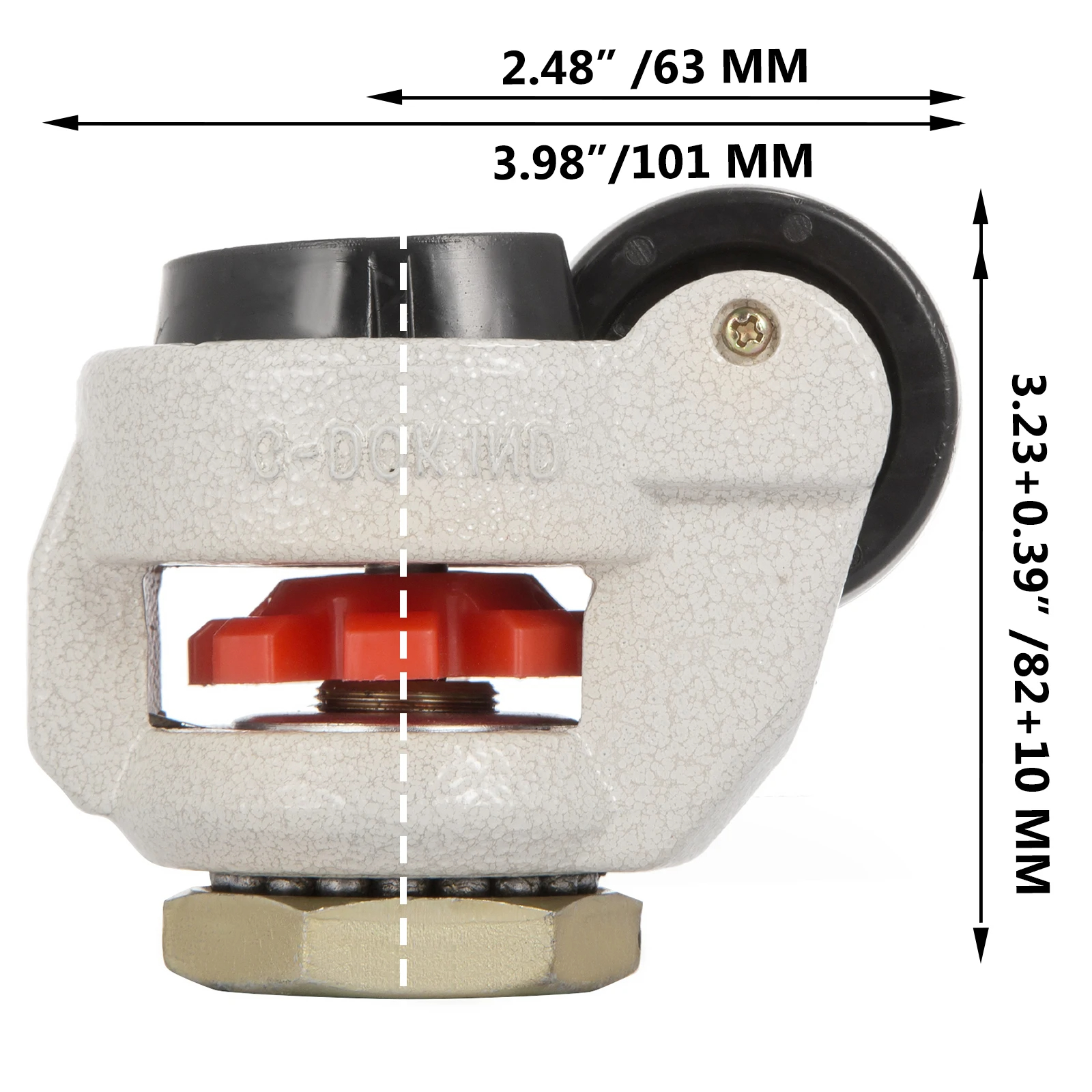

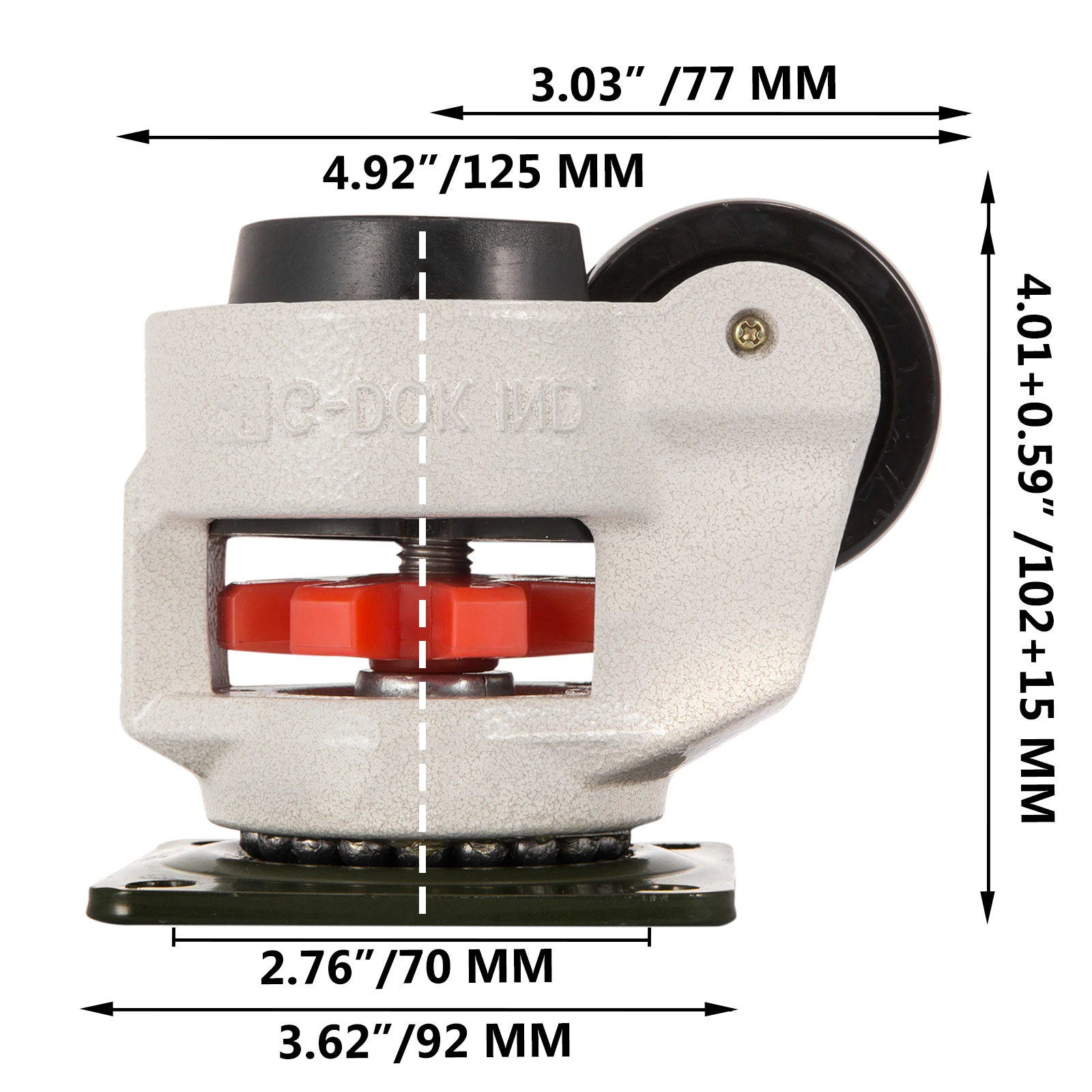

- Wheel Diameter: The diameter of the caster’s wheels can be customized to meet specific load capacity and mobility needs. Larger wheels distribute weight more evenly and provide better stability.

- Wheel Tread Design: The tread pattern of the caster’s wheels can be customized for enhanced grip and maneuverability on various surfaces. Some treads are designed for smooth surfaces, while others are suitable for rough terrain or uneven floors.

- Load Capacity: Heavy-duty casters can be manufactured with varying load capacity ratings to accommodate different weight requirements. Customizable load capacities ensure that the casters can handle the specific loads of the equipment or materials being transported.

These customizable aspects of heavy-duty casters allow for precise tailoring to the requirements of diverse industries and applications, ensuring optimal performance, safety, and efficiency in material handling and transportation tasks.

There are several packaging solutions available for heavy duty casters, including:

- Bulk Packaging: Bulk packaging involves placing multiple heavy-duty casters in large containers, such as boxes or crates. This method is often used for shipping casters in high quantities to manufacturing facilities or distributors.

- Individual Packaging: For retail or smaller orders, heavy-duty casters can be individually packaged. Each caster is placed in its own protective container, which may be a plastic bag or a cardboard box, to prevent scratching, damage, or contamination.

- Reel Packaging: Heavy-duty casters with large wheel diameters or in specific quantities may be packaged on reels. This packaging method is convenient for transportation and storage and allows for easy handling during assembly.

- Palletized Packaging: Heavy-duty casters are arranged on pallets and secured for shipping. This packaging solution is ideal for larger quantities of casters and simplifies the loading and unloading process using forklifts or pallet jacks.

- Custom Packaging: Custom packaging solutions are tailored to the specific requirements of the caster type, application, or customer preferences. Custom packaging can include foam inserts, protective wraps, or specialized containers to ensure the safety and security of the casters during transit.

- Eco-Friendly Packaging: Environmentally conscious packaging options are becoming increasingly popular. These solutions use recyclable or biodegradable materials to minimize waste and reduce the environmental impact of packaging.

Packaging solutions for heavy-duty casters aim to protect the products from damage, ensure safe transportation, and provide convenient handling for manufacturers, suppliers, and end-users. The choice of packaging method depends on factors like the quantity, type, and destination of the casters, as well as specific customer requirements and industry standards.