Features of groove casters include:

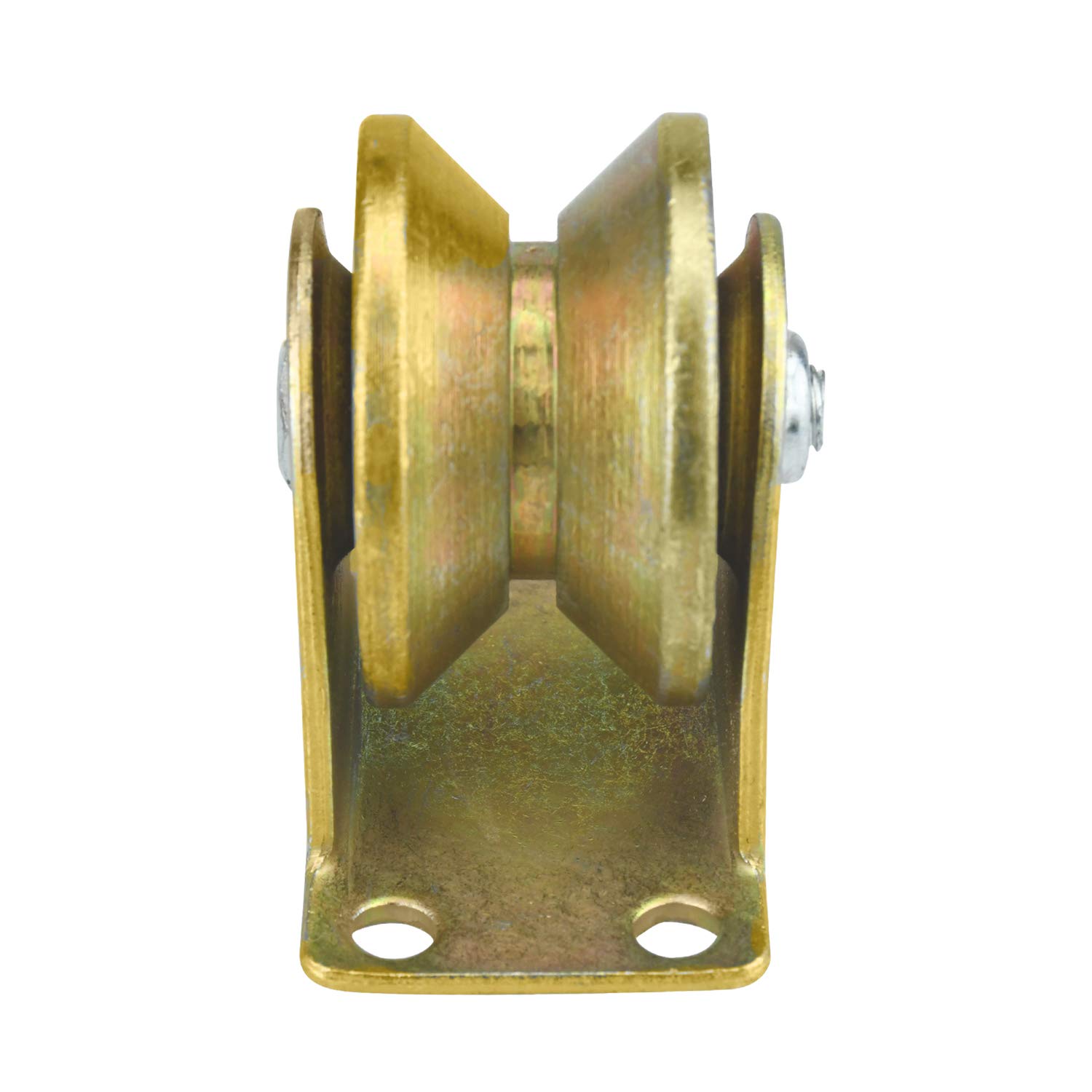

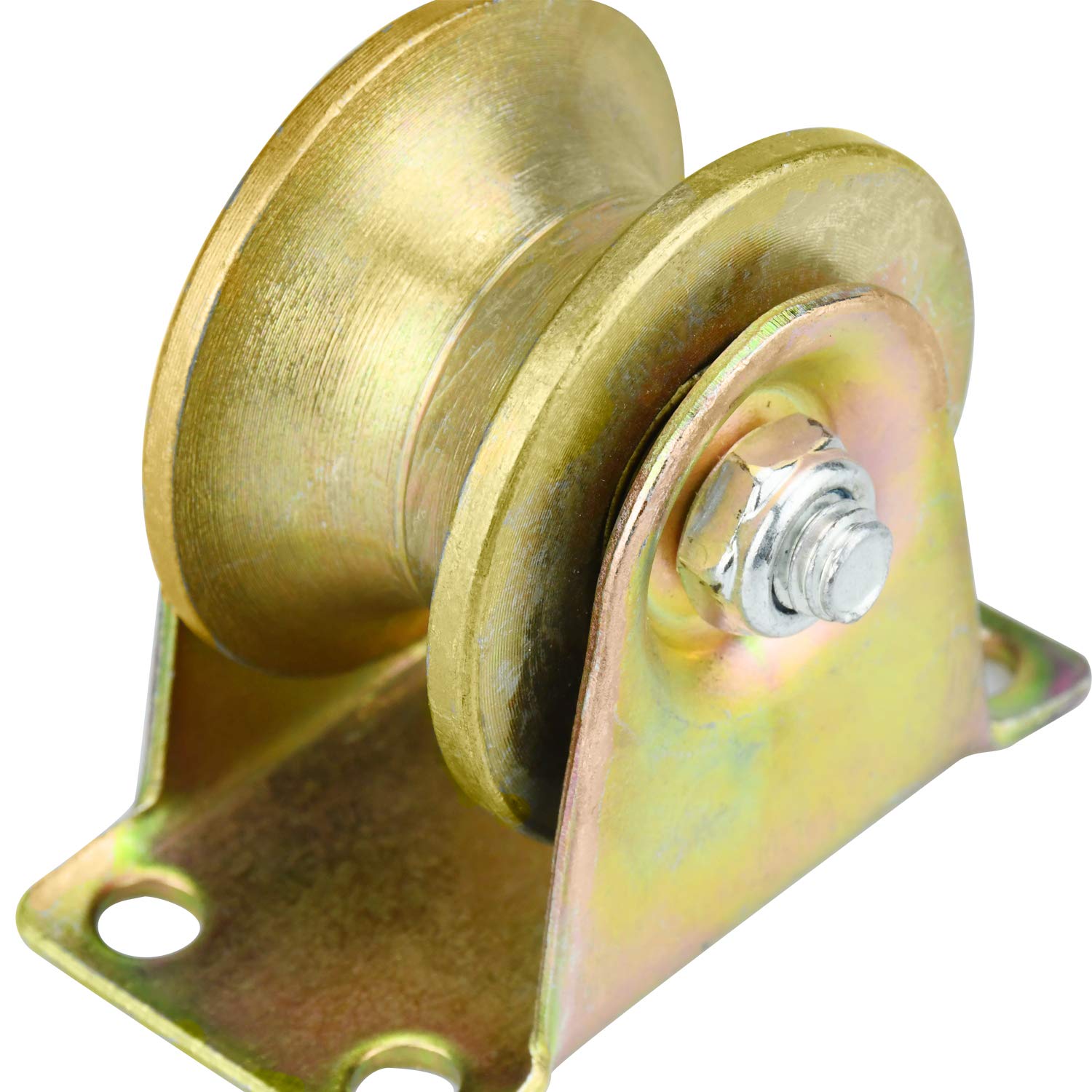

- Grooved Wheel: Groove casters have a wheel with a groove or channel in the center of the wheel. This groove is designed to accommodate and track along a rail, track, or other similarly designed surface.

- Track Alignment: The grooved wheel is designed to maintain alignment with the track or groove, ensuring smooth and controlled movement along the intended path.

- High Load Capacity: Groove casters are often built to handle heavy loads. Their design allows them to distribute weight evenly on the track, providing stability and reducing the risk of derailment.

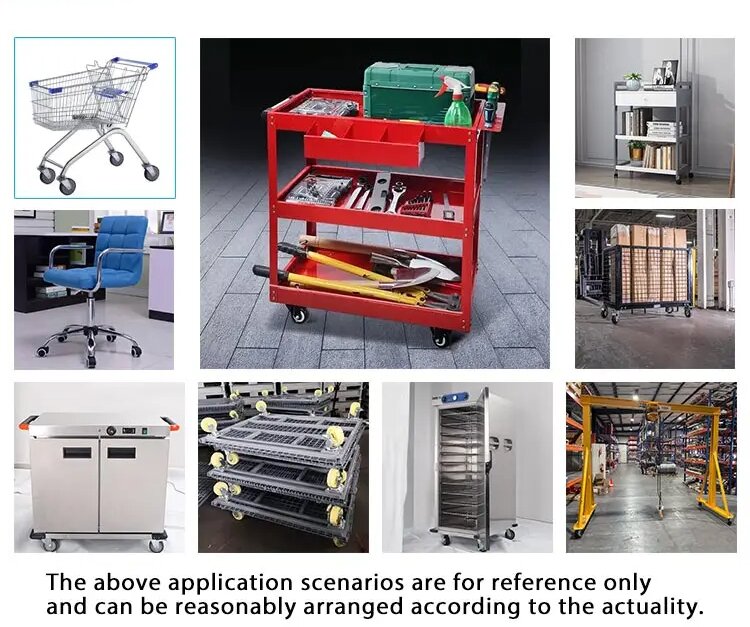

- Precision and Stability: These casters are known for their precision and stability. They are commonly used in applications that require accurate and controlled movement, such as industrial and manufacturing settings.

Overall, groove casters are designed to provide controlled and precise movement along a designated path, making them essential for various industrial and manufacturing applications where accuracy and stability are paramount.

Groove casters offer several advantages, including:

- Quiet Operation: Groove casters operate quietly due to reduced friction. This is particularly beneficial in applications where noise reduction is essential, such as in warehouses, factories, and other industrial settings.

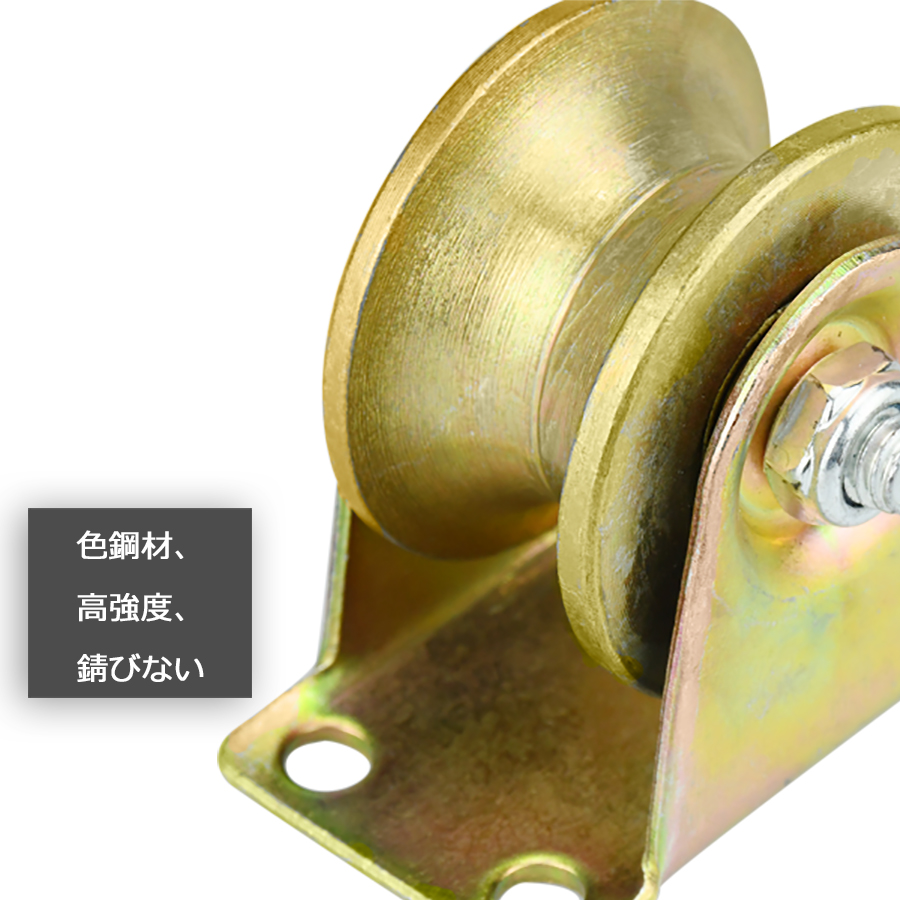

- Durability: These casters are typically built to withstand demanding environments. They are often constructed from materials like steel or heavy-duty polymers, ensuring longevity even in challenging conditions.

- Precise Tracking: Groove casters are excellent at maintaining their path without wandering. This precise tracking is crucial for applications that require materials to be transported or positioned with precision.

- Customization: Groove casters are available in a variety of wheel materials and configurations, allowing for customization based on specific application needs. Whether it’s the type of wheel material or the size of the caster, there are options to suit various requirements.

In summary, groove casters offer a range of advantages, including precise movement, stability, heavy load capacity, reduced friction, quiet operation, durability, and customization options. These features make groove casters a preferred choice in many industrial and material handling applications where accuracy and reliability are essential.

Customizable aspects of groove casters include:

- Wheel Material: Groove casters can be customized with different wheel materials to suit specific requirements. Common wheel materials include rubber, polyurethane, steel, and various specialty compounds. The choice of material depends on factors like load capacity, floor type, and environmental conditions.

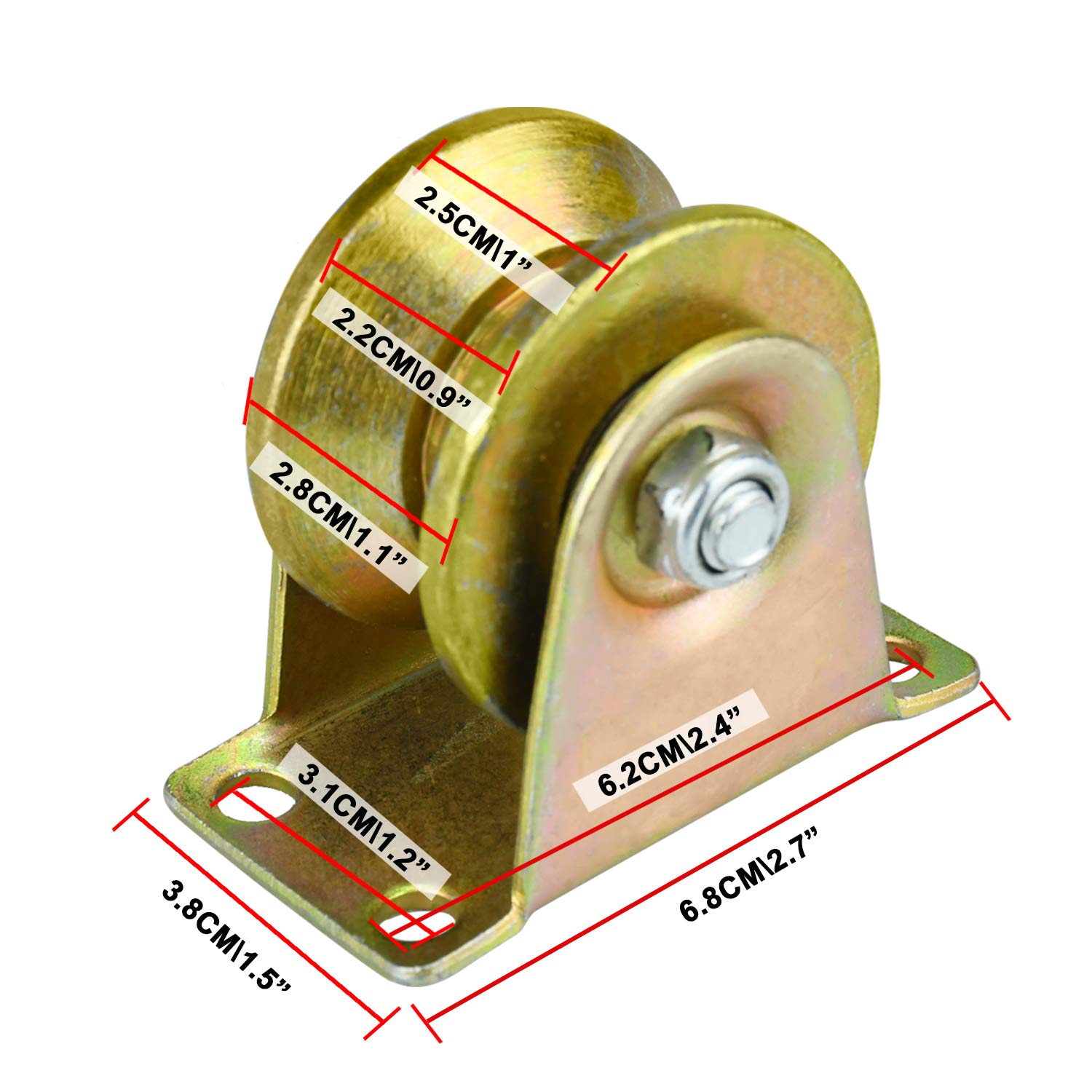

- Wheel Diameter: The wheel diameter can be tailored to meet the specific needs of an application. Smaller wheel diameters provide greater maneuverability in confined spaces, while larger wheels offer stability and smoother movement on uneven surfaces.

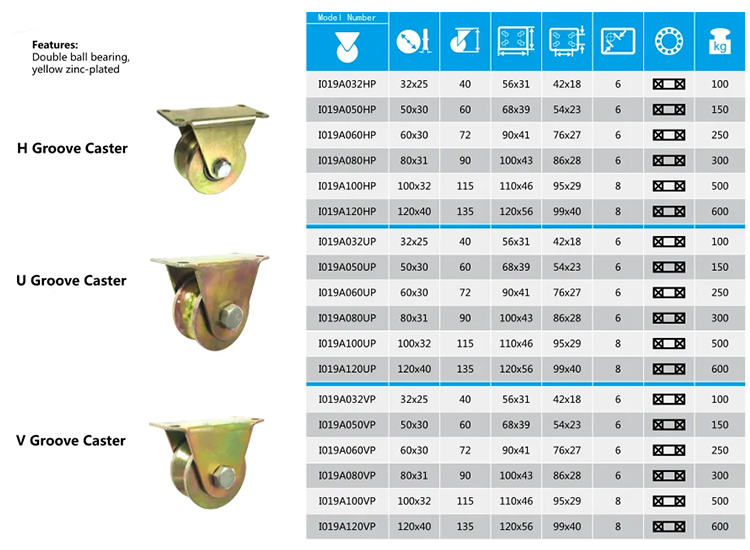

- Load Capacity: Groove casters come in various load capacity ratings. Customization allows for the selection of casters that can handle the expected weight of the load being transported. This ensures safe and efficient material handling.

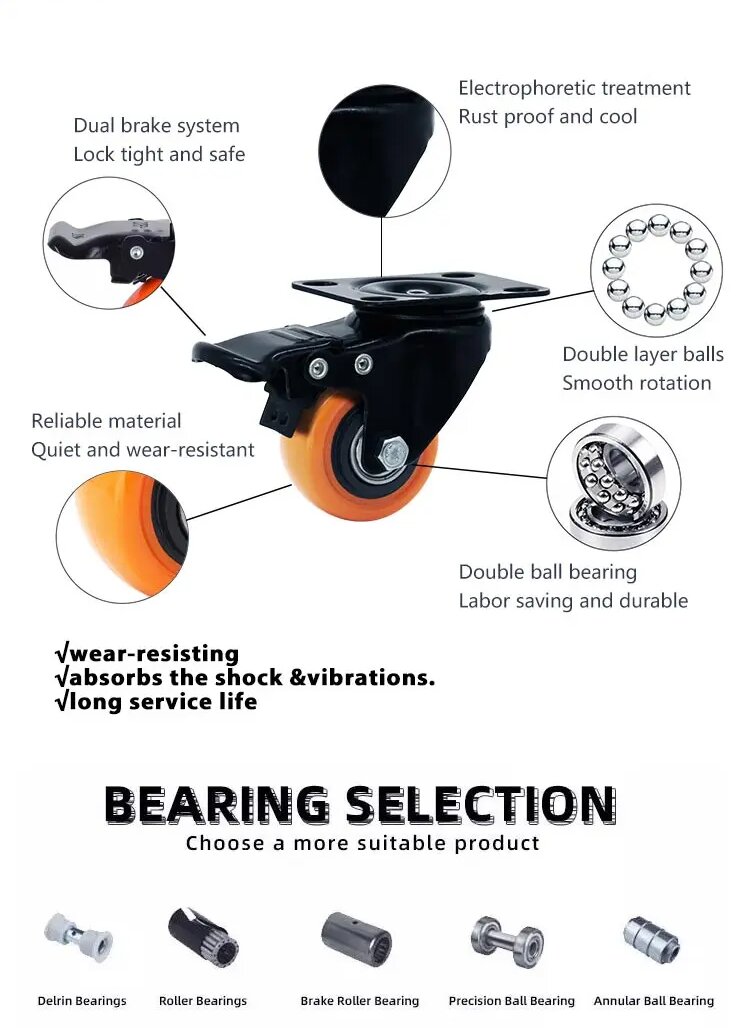

- Bearing Type: The type of bearings used in groove casters can be customized. Bearings impact the ease of rolling and maneuverability. Options include ball bearings for smooth rolling and roller bearings for handling heavier loads.

- Locking Mechanisms: Some groove casters can be customized with locking mechanisms. These mechanisms allow the caster to be secured in place, preventing unintended movement. The type and configuration of the locking mechanism can be tailored to specific needs.

- Groove Size and Configuration: The size and configuration of the groove in the caster’s wheel can be customized to match the dimensions and shape of the track or rail it will run on. This ensures a precise fit and optimal performance.

By offering these customizable aspects, groove casters can be precisely tailored to the unique requirements of various material handling applications, ensuring optimal performance and safety.

There are several packaging solutions available for groove casters, including:

- Individual Packaging: Groove casters are often packaged individually in boxes or plastic bags. This packaging is suitable for single-caster purchases and provides protection during storage and transportation.

- Bulk Packaging: For customers who require multiple groove casters, bulk packaging options are available. Casters are typically grouped together and packaged in larger containers, such as cardboard boxes or plastic crates. This packaging solution is efficient for businesses that purchase casters in larger quantities.

- Blister Packaging: Some groove caster manufacturers offer blister packaging. In this packaging solution, individual casters are placed within a clear plastic blister pack, which provides visibility and protection. Blister packaging is often used for retail display, allowing customers to see the product before purchase.

- Reel Packaging: Groove casters may be packaged on reels, especially when they are intended for use in assembly lines or automated systems. This packaging allows for easy unwinding and installation of casters, reducing handling time and improving efficiency during installation.

- Custom Packaging: Manufacturers may offer custom packaging solutions based on the specific needs of customers. Custom packaging can include branding, labels, or packaging materials tailored to the customer’s preferences.

- Eco-Friendly Packaging: Some companies opt for eco-friendly packaging options, such as cardboard boxes made from recycled materials or biodegradable packaging. These solutions align with sustainability goals and environmentally conscious practices.

The choice of packaging solution often depends on the caster manufacturer, customer preferences, and the intended use of the casters. It’s essential for manufacturers to provide appropriate packaging to ensure that the casters arrive in excellent condition and are ready for use in various applications.