Features of pneumatic casters include:

- Shock absorption: Pneumatic casters are known for their excellent shock absorption capabilities. The air-filled tires act as cushions, reducing the impact and vibration that can be transmitted to the objects being transported. This makes them suitable for delicate or fragile loads.

- Smooth and quiet operation: Pneumatic casters provide a smooth and quiet rolling experience. The air-filled tires dampen noise and vibrations, making them ideal for environments where noise is a concern, such as hospitals or quiet workplaces.

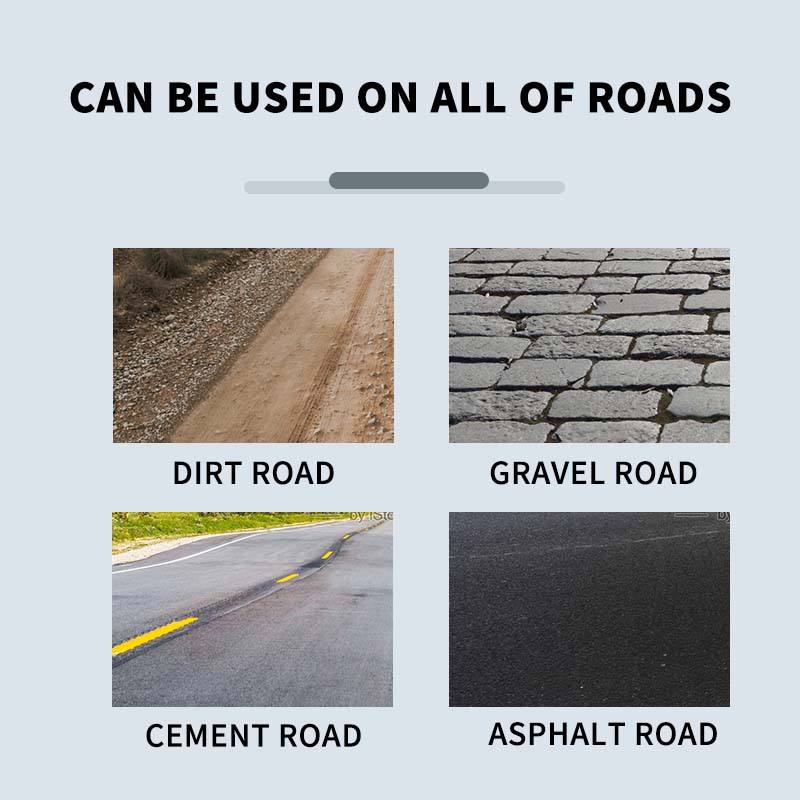

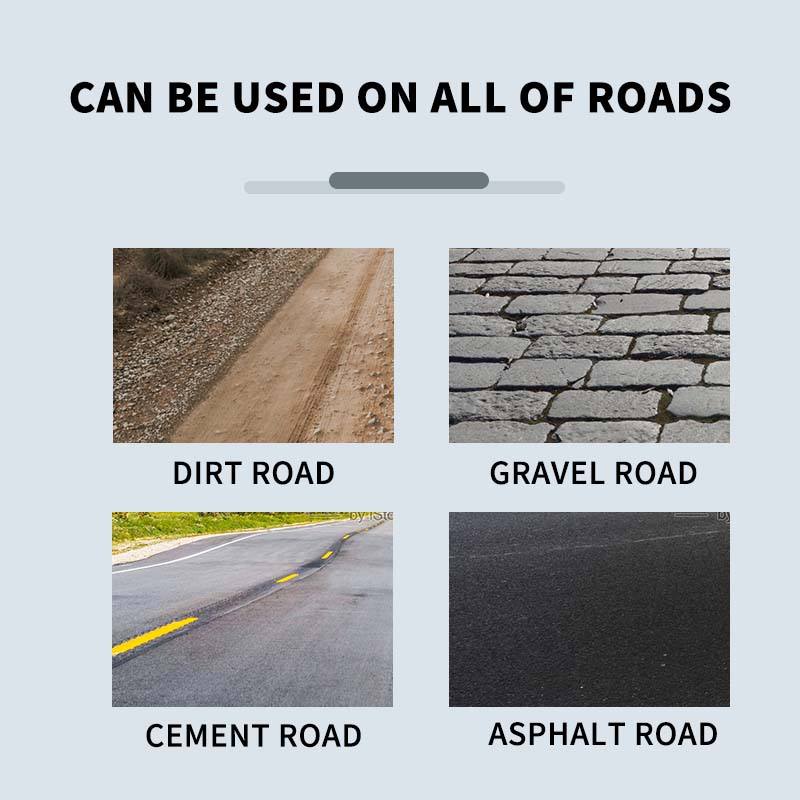

- Versatility: Pneumatic casters are well-suited for use on a variety of surfaces, including uneven, rough, or outdoor terrains. They can traverse obstacles like gravel, grass, and cracks in the floor more effectively than some other caster types.

- Load capacity: Pneumatic casters come in different load capacity options to meet various needs. Some heavy-duty models can handle substantial weight while maintaining their shock-absorbing properties.

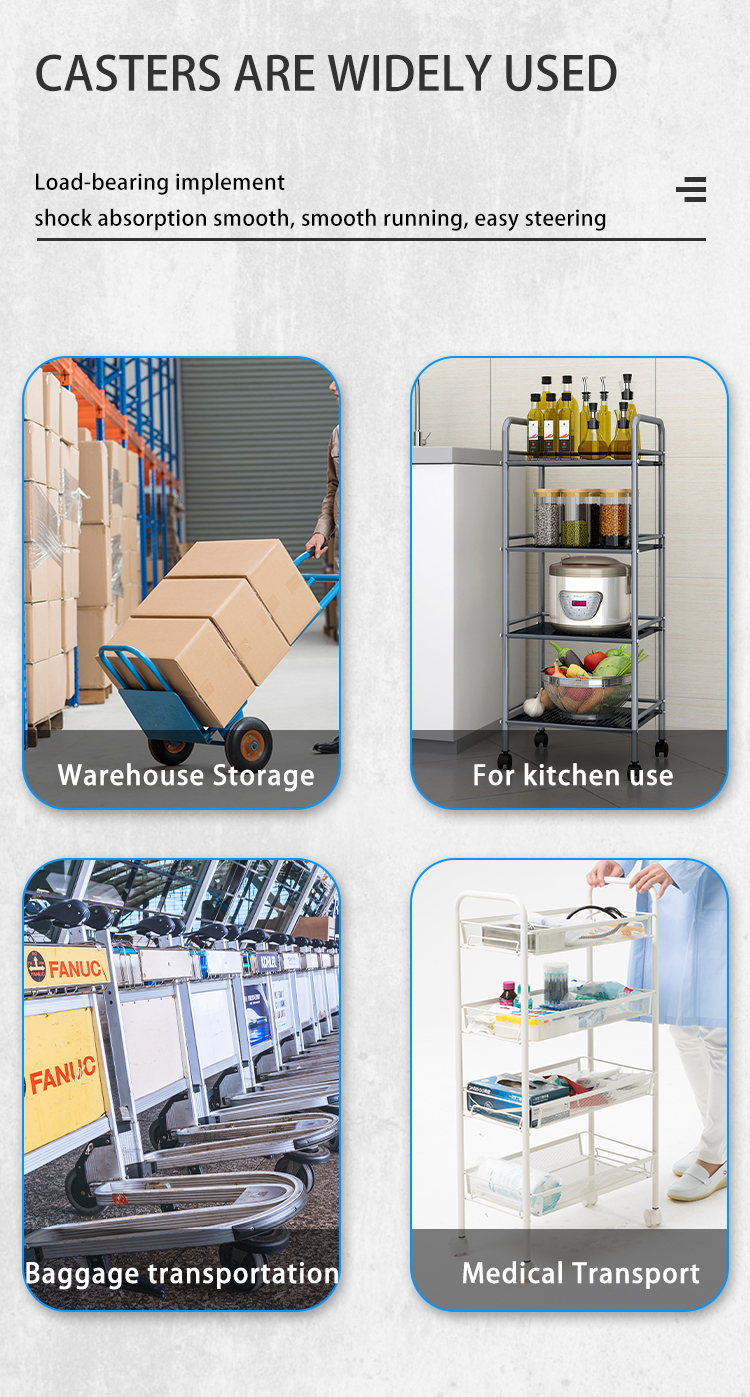

Overall, pneumatic casters are a popular choice when you need to transport loads over uneven or rough terrain while minimizing the potential for damage and noise. They are commonly used in industries such as material handling, automotive, aviation, and outdoor equipment applications.

Pneumatic casters offer several advantages, including:

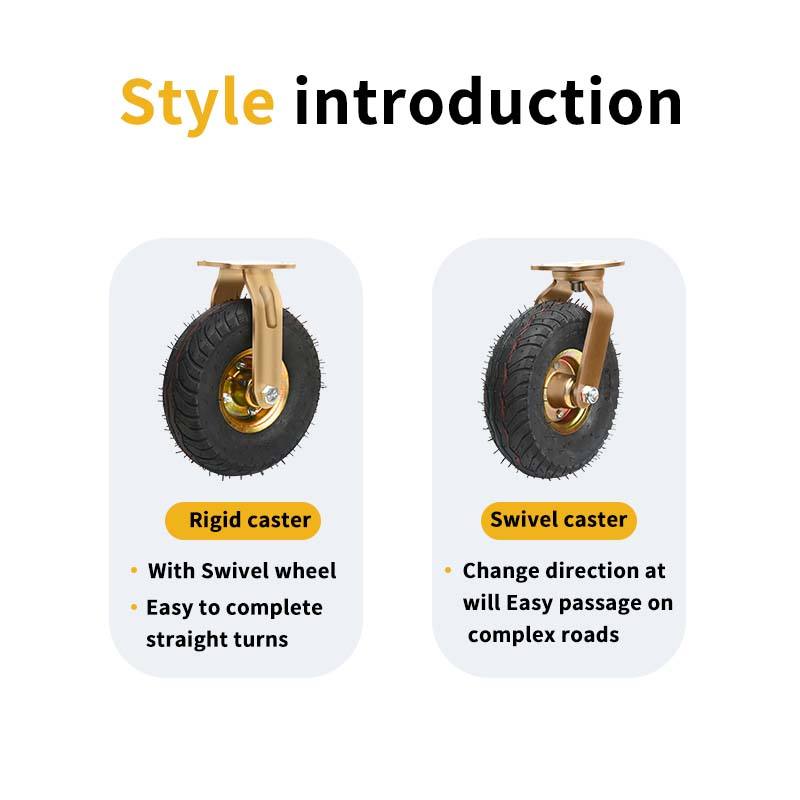

- Mobility and Maneuverability: Pneumatic casters offer good mobility and maneuverability. They are capable of swiveling and turning easily, allowing for precise navigation around obstacles and tight spaces.

- Low Rolling Resistance: Pneumatic casters typically have lower rolling resistance compared to some other caster types. This means less effort is required to move heavy loads, making them more user-friendly.

- Reduced Floor Wear: The cushioning effect of pneumatic casters helps reduce wear and tear on both the caster wheels and the floor, extending the life of both. This is particularly important when dealing with sensitive floor surfaces.

- Tire Options: Pneumatic casters come with a variety of tire options, including different tread patterns and materials. Users can choose the tire type that best suits their specific application and surface conditions, ensuring optimal performance.

Overall, pneumatic casters are a reliable choice for applications that demand a combination of shock absorption, smooth and quiet operation, versatility, and load-bearing capacity. They are commonly used in a wide range of industries, including material handling, aerospace, automotive, and outdoor equipment applications.

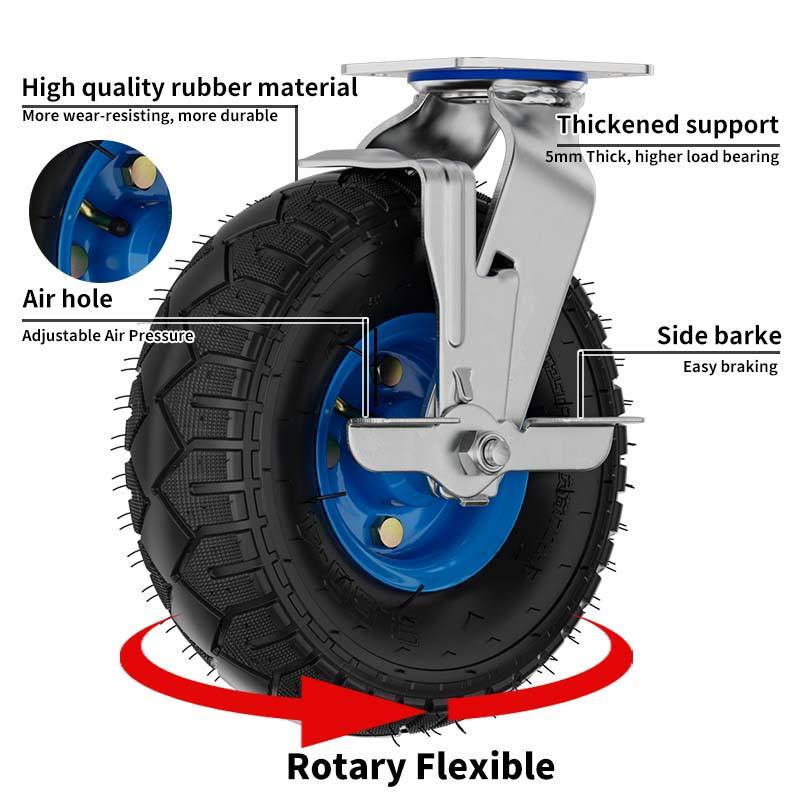

Customizable aspects of pneumatic casters include:

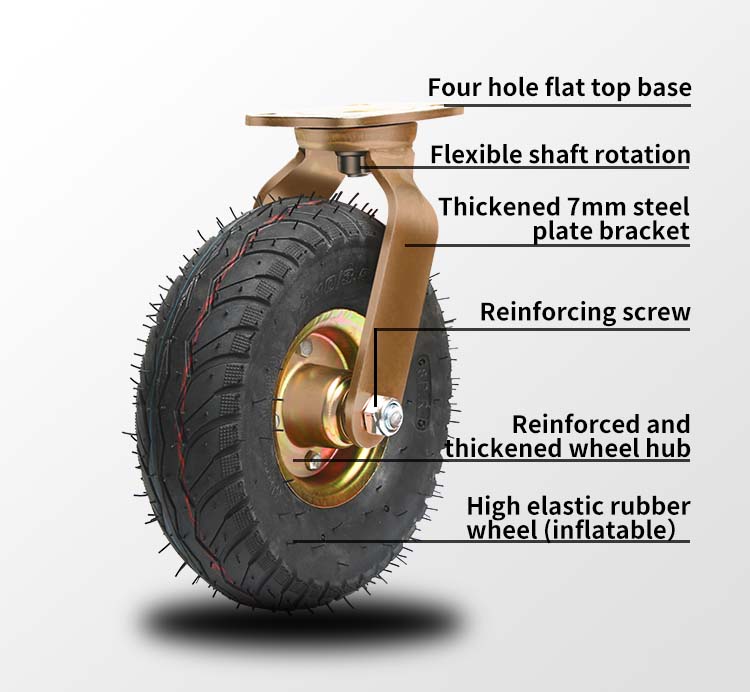

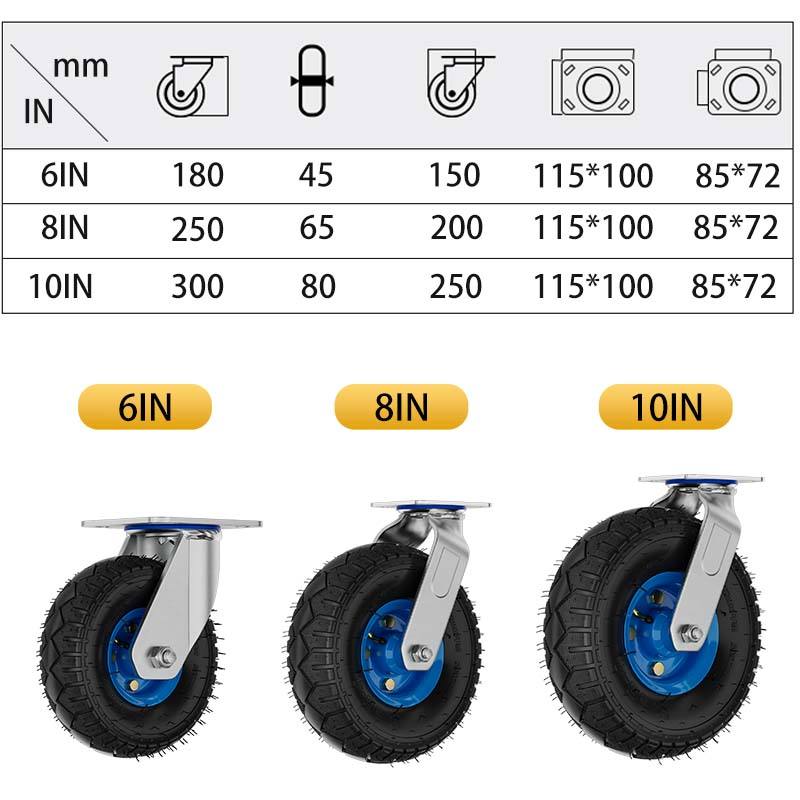

- Caster Size: Pneumatic casters come in various sizes to accommodate different load capacities and applications. The size of the caster wheel can be customized to match the specific load-bearing needs of the equipment.

- Load Capacity: Pneumatic casters are available in different load capacity ratings. You can select casters with higher load capacities for heavier loads or applications that require increased weight-bearing capabilities.

- Tire Type: Pneumatic casters offer a choice of tire types, including different tread patterns and materials. The selection of the tire type can be customized to suit the specific surface conditions and requirements of the application. Common tire materials include rubber, foam-filled, and pneumatic (air-filled) tires.

- Wheel Diameter: The diameter of the caster wheel can be customized based on the application’s needs. Larger wheels may offer better stability and ease of rolling over rough terrain, while smaller wheels can be suitable for tight spaces.

- Wheel Material: The material of the caster wheel itself can be customized. Common wheel materials include various types of rubber, plastic, and sometimes metal for heavy-duty applications.

- Wheel Bearings: The type of wheel bearings used in pneumatic casters can be customized. Choices may include precision ball bearings, roller bearings, or plain bore bearings. The selection can impact the caster’s ease of rolling and load capacity.

The customization options available for pneumatic casters provide flexibility in tailoring these caster wheels to meet the specific needs and challenges of different applications, whether for industrial equipment, furniture, medical carts, or outdoor utility vehicles. It’s essential to consider these customizable aspects when selecting pneumatic casters to ensure they perform optimally in your particular situation.

There are several packaging solutions available for pneumatic casters, including:

- Bulk Packaging: Pneumatic casters can be bulk-packaged for convenience when customers need a larger quantity of casters. They are typically packed in cartons or containers, with multiple casters of the same type and size placed together. Bulk packaging is cost-effective and efficient for handling large orders.

- Retail Packaging: For individual sales to end-users, pneumatic casters can be packaged in retail-friendly packaging. This packaging often includes product information, branding, and may have a clear plastic window to allow customers to view the caster. It’s designed to be eye-catching and informative.

- Blister Packaging: Blister packaging involves sealing pneumatic casters in clear plastic shells with a cardboard backing. This packaging method is commonly used for smaller quantities and is ideal for retail environments. It allows customers to see the product while keeping it secure.

- Boxed Sets: In some cases, pneumatic casters are sold in boxed sets, which may include a combination of swivel and rigid casters along with necessary mounting hardware. Boxed sets can be convenient for customers who need a complete caster solution for a specific application.

- Foam Inserts: When shipping or storing sensitive and delicate pneumatic casters, foam inserts can be used. These inserts are custom-designed to cradle the casters and protect them from damage during transit. Foam inserts are often used in combination with bulk packaging.

- Plastic Bags: Pneumatic casters may be individually or collectively placed in plastic bags to protect them from dust, moisture, and minor scratches during storage or shipping.

Packaging solutions for pneumatic casters play a crucial role in ensuring the safe delivery of the products to customers and protecting them from damage. The choice of packaging will depend on the specific needs of the product, the customer, and the distribution method.