Features of shock absorbing casters include:

- Spring-loaded or suspension system: Shock-absorbing casters are equipped with springs or suspension systems that can absorb and dissipate shocks and vibrations. These systems compress and expand to cushion the impact and reduce the transfer of shock to the equipment or structure.

- Rubber or elastomeric wheels: These casters often have wheels made of rubber or other elastomeric materials, which can provide additional shock absorption and reduce noise and vibration.

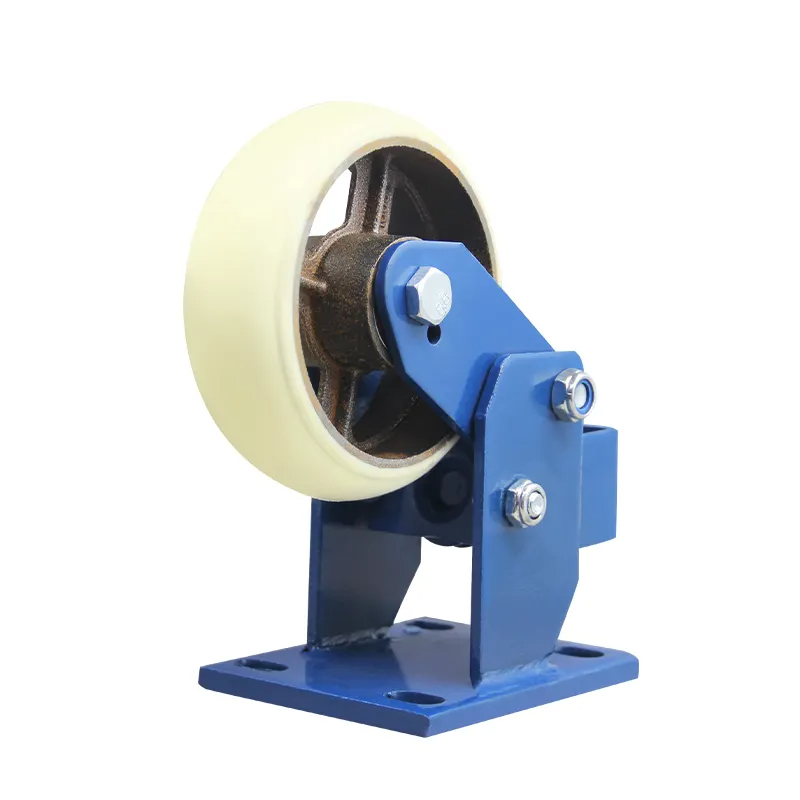

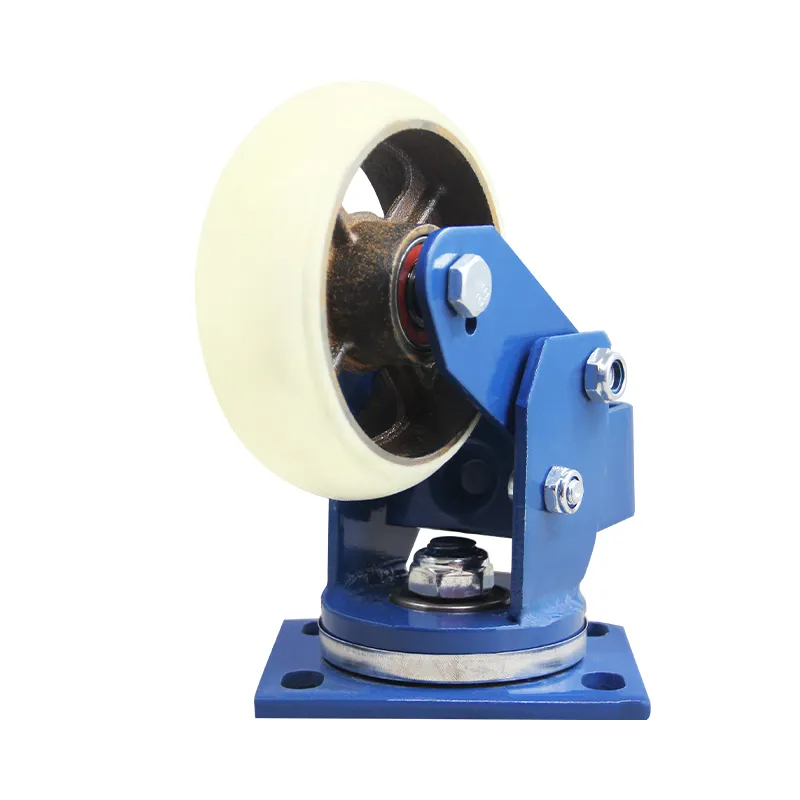

- Swivel and locking mechanisms: Many shock-absorbing casters are designed with swivel mechanisms, allowing for easy maneuverability. Some may also include locking features to stabilize the equipment when necessary.

- Load capacity: Shock-absorbing casters are available in various load capacities to accommodate different applications. It’s important to choose casters with a load capacity that matches the weight of the equipment or object they will support.

Shock-absorbing casters are commonly used in applications where reducing shock, vibration, and noise is critical, such as in material handling, medical equipment, industrial machinery, and laboratory equipment. The specific features and design of shock-absorbing casters can vary depending on the intended application and the manufacturer.

Shock absorbing casters offer several advantages, including:

- Enhanced stability: The shock-absorbing properties of these casters provide added stability to equipment, preventing wobbling or toppling in applications where stability is crucial.

- Smoother movement: The suspension and damping systems in shock-absorbing casters ensure a smoother and more controlled movement of equipment, making it easier to transport items without disruption.

- Improved product quality: In manufacturing and production environments, shock-absorbing casters can help maintain product quality by preventing damage or contamination due to excessive vibrations.

- Increased safety: By reducing the risk of equipment tipping over or components breaking due to shock, these casters enhance workplace safety.

Overall, shock-absorbing casters are a valuable addition to equipment and systems that require protection from shocks and vibrations. They contribute to improved performance, safety, and the longevity of equipment while enhancing the overall work environment.

Customizable aspects of shock absorbing casters include:

- Load capacity: Shock-absorbing casters can be customized to support different load capacities. Manufacturers can adjust the caster’s design, materials, and components to ensure it can handle the weight of the equipment or object it will be supporting.

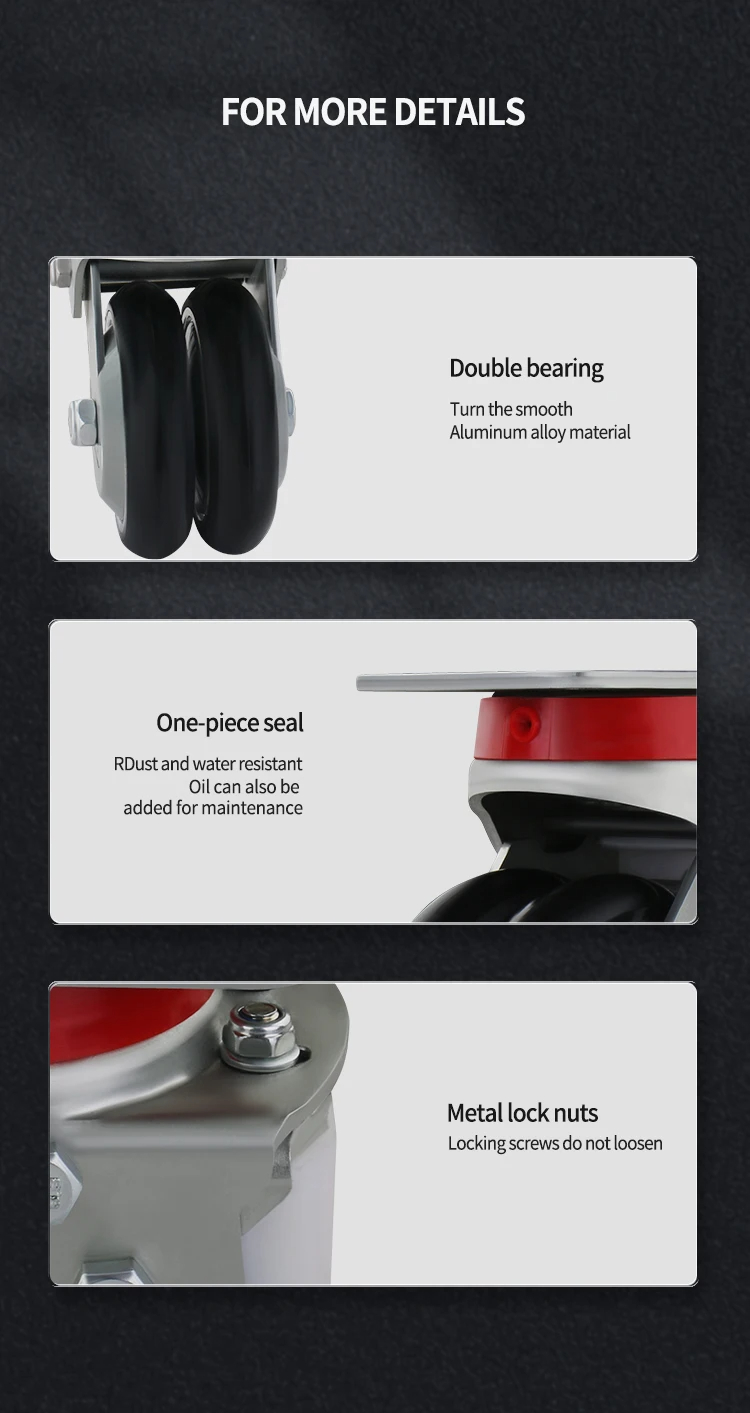

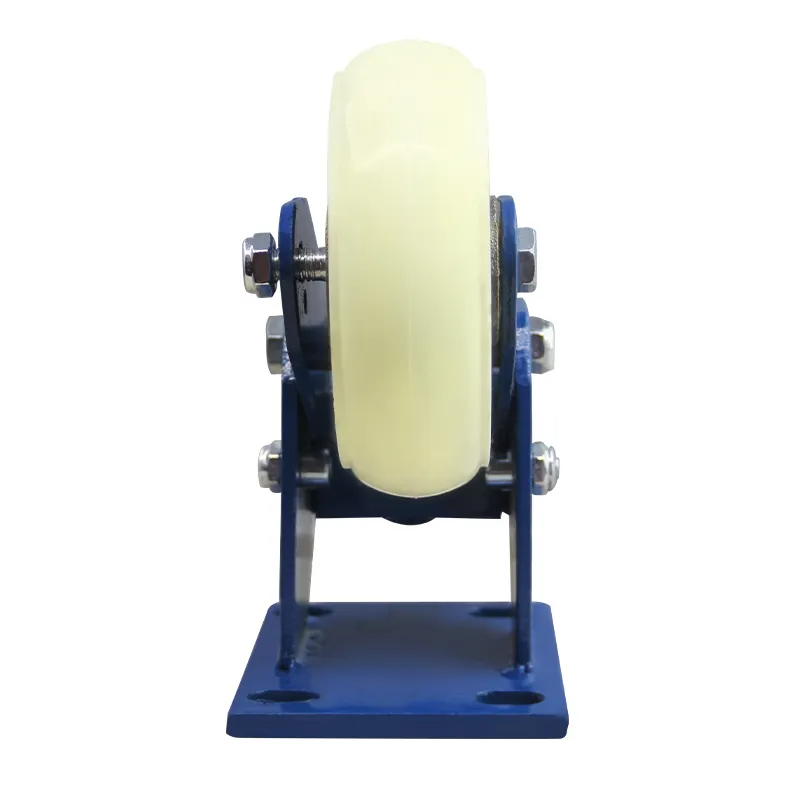

- Wheel material and type: The type of wheel and the material used can be customized to suit the application. Different wheel materials, such as rubber, polyurethane, or nylon, can be chosen based on factors like floor type, noise level, and durability.

- Wheel diameter: The diameter of the wheels can be customized to meet the specific needs of the application. Larger wheels can provide better mobility and stability, while smaller wheels may be suitable for more confined spaces.

- Suspension system: The suspension system or shock-absorbing mechanism itself can be tailored to provide the desired level of shock absorption and vibration isolation. This may involve adjusting the type and strength of the suspension components, such as springs or elastomers.

- Caster configuration: Custom configurations can include the number of casters on an equipment unit, the layout, and the caster’s positioning for optimal stability and maneuverability.

- Mounting options: Shock-absorbing casters can be customized for different mounting methods, including plate mounts, stem mounts, or custom configurations to fit the specific needs of the equipment or application.

Customizable shock-absorbing casters are especially useful when you have unique requirements or specific challenges in your application. Manufacturers can work with you to design and produce casters that are tailored to your specific needs and performance expectations.

There are several packaging solutions available for shock absorbing casters, including:

- Individual packaging: Each caster is separately packaged in its own box or bag. This is a common packaging method that provides protection and prevents damage during shipping and handling. Individual packaging is especially useful for smaller casters.

- Bulk packaging: Casters are packaged together in bulk, typically in a larger box or container. This method is cost-effective and efficient for shipping larger quantities of casters at once.

- Blister packaging: Some casters may be placed in blister packs made of clear plastic. This packaging method allows customers to see the product while still providing protection.

- Corrugated boxes: Casters can be packed in corrugated cardboard boxes, which provide excellent protection against impacts during shipping. These boxes can be customized in various sizes to accommodate different caster dimensions.

- Foam or foam inserts: To offer superior shock protection, foam inserts can be used within the packaging. These inserts are designed to precisely fit the casters and provide cushioning during transit.

- Bubble wrap or padding: Bubble wrap or other padding materials can be used to wrap individual casters or fill empty spaces within the packaging to prevent movement and cushion against shocks.

The choice of packaging solution may depend on the caster’s size, quantity, and the specific requirements of the manufacturer and customer. Proper packaging helps ensure that the shock-absorbing casters are delivered in excellent condition and ready for use upon arrival, reducing the risk of any damage during transit.