Features of twin-wheel casters include:

- Enhanced Load Capacity: Twin-wheel casters are designed to distribute weight across two wheels, which allows them to support heavier loads compared to single-wheel casters of the same size.

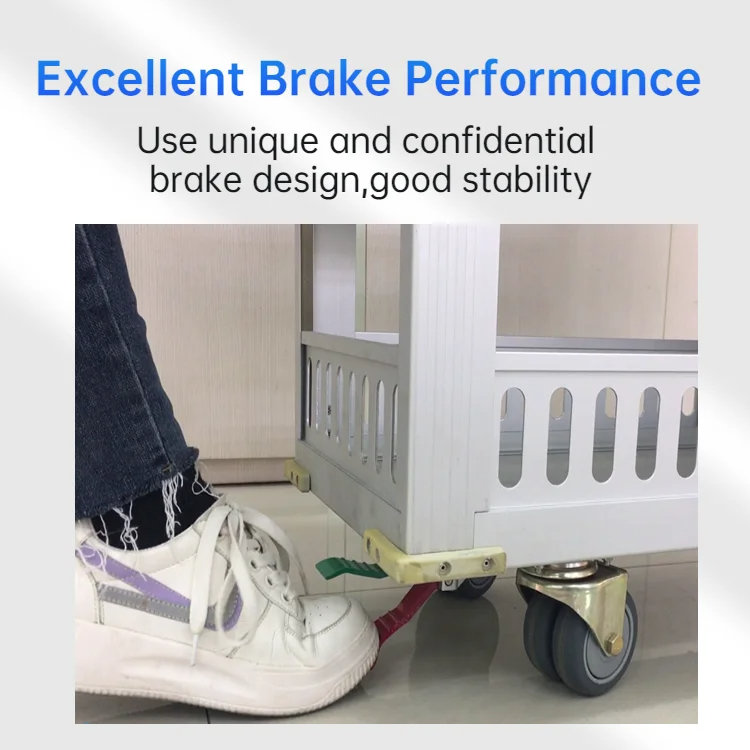

- Improved Stability: The dual-wheel design offers greater stability and balance, reducing the risk of tipping or wobbling, particularly when carrying heavy loads.

- Smooth and Even Rolling: Twin-wheel casters provide smoother and more even rolling, allowing for easy maneuverability, even on uneven surfaces.

- Reduced Floor Wear: The dual-wheel configuration reduces the amount of pressure applied to the floor, minimizing floor wear and potential damage.

These features make twin-wheel casters a popular choice for a wide range of applications where stability, load capacity, and smooth mobility are essential.

Twin-wheel casters offer several advantages, including:

- Greater Swivel Range: Twin-wheel casters often offer a larger swivel range, allowing for improved maneuverability. This feature enables users to navigate tight spaces and make precise movements when necessary.

- Noise Reduction: Compared to single-wheel casters, twin-wheel casters tend to produce less noise during operation. This makes them suitable for environments where noise levels need to be kept to a minimum, such as office spaces or hospitals.

- Durability and Longevity: The dual-wheel design distributes the load more evenly, reducing the wear and tear on individual wheels. This promotes longer caster lifespan and reduces the frequency of maintenance and replacement.

- Versatility: Twin-wheel casters are versatile and find application in a wide range of industries, from office furniture and medical equipment to display units and retail fixtures. Their adaptability makes them a popular choice for various settings.

In summary, twin-wheel casters offer numerous advantages that make them an excellent choice for applications where stability, load capacity, smooth mobility, and floor protection are paramount. Their versatility and durability ensure they can meet the demands of a wide range of industries and settings.

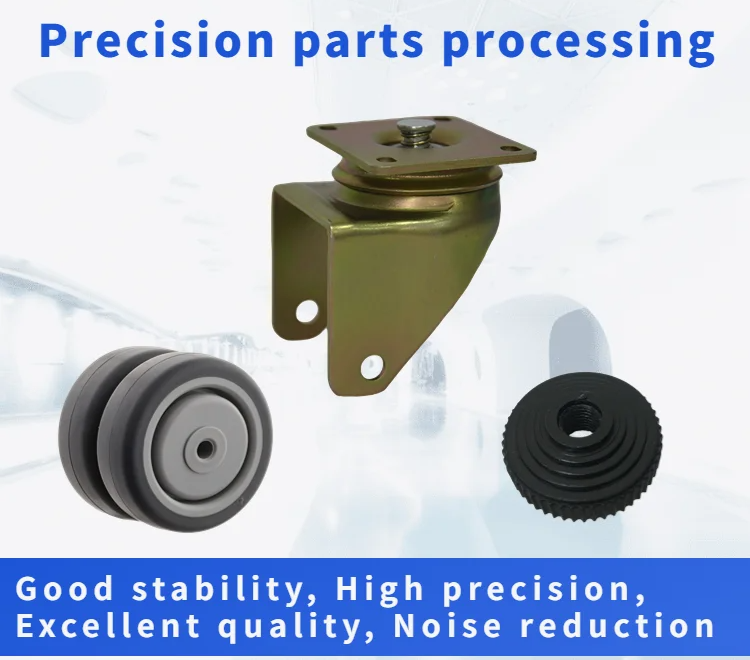

Customizable aspects of twin-wheel casters include:

- Wheel Material: Twin-wheel casters are available with wheels made from various materials, including rubber, polyurethane, hard plastic, and metal. The choice of wheel material can be customized to suit different flooring types and specific applications.

- Wheel Size: The diameter and width of the caster wheels can often be customized to meet load capacity and mobility requirements. Larger wheels are suitable for heavy loads and rough terrain, while smaller wheels are more space-efficient and maneuverable in tight spaces.

- Wheel Tread Design: The tread pattern on the caster wheels can be customized to provide specific traction and durability characteristics. Tread designs can vary from smooth wheels to ribbed, grooved, or treaded patterns.

- Load Rating: Twin-wheel casters are available in a range of load ratings to accommodate various weight capacities. Custom load ratings can be specified to meet the demands of specific applications.

The ability to customize these aspects allows users to tailor twin-wheel casters to meet the specific needs of their applications, whether in industrial settings, medical equipment, office furniture, or other diverse environments.

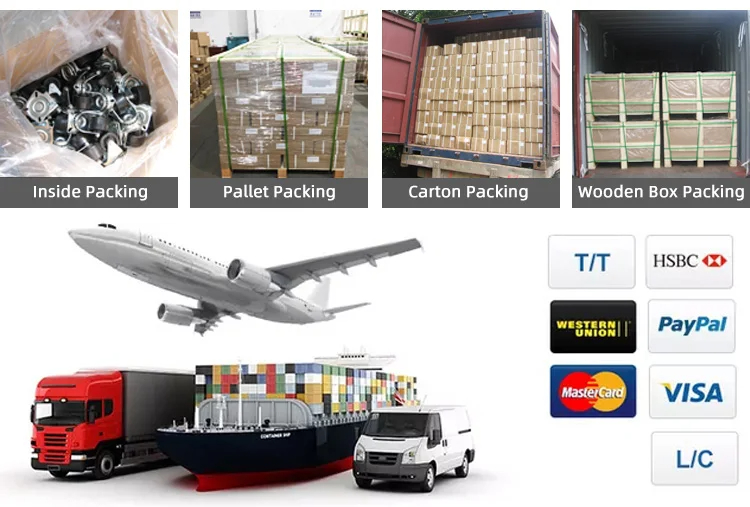

There are several packaging solutions available for twin-wheel casters , including:

- Bulk Packaging: Twin-wheel casters are often available in bulk packaging, where multiple casters are bundled together in a single box. This packaging solution is suitable for industrial or commercial customers who require a larger quantity of casters for their operations. Bulk packaging is cost-effective and reduces waste.

- Individual Packaging: Some twin-wheel casters are individually packaged in separate boxes. This type of packaging is convenient for customers who only need a few casters or those who want each caster to be separately labeled and protected during transportation.

- Blister Packaging: Blister packaging involves placing each twin-wheel caster in a transparent plastic blister or bubble. This packaging is commonly used for retail display purposes, allowing customers to see the product while keeping it protected from damage or contamination.

- Cardboard Boxes: Twin-wheel casters may be packaged in standard cardboard boxes, providing protection during shipping and storage. These boxes can be customized with labels, barcodes, and product information for easy identification.

The choice of packaging solution for twin-wheel casters depends on factors such as the intended use, customer preferences, and environmental considerations. It’s important to select packaging that ensures the safe delivery of the casters while aligning with the needs and values of the end user or industry.