Features of swivel casters include:

- 360-Degree Rotation: Swivel casters can rotate a full 360 degrees, allowing for unrestricted movement in any direction. This feature provides exceptional maneuverability and makes them ideal for applications requiring tight turns and precise navigation.

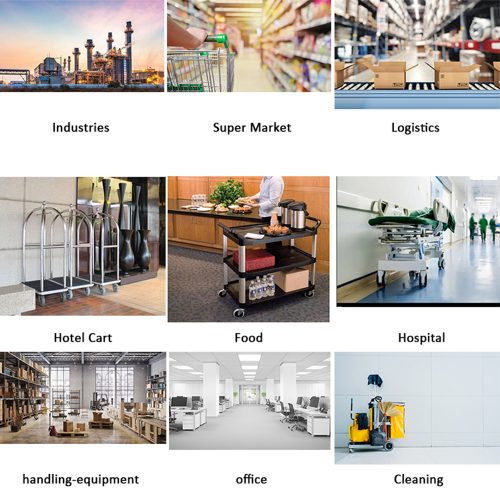

- Enhanced Maneuverability: Swivel casters excel in applications where the ability to change direction quickly and smoothly is essential. They are commonly used in environments where flexibility and agility are key, such as in industrial settings, warehouses, and healthcare facilities.

- Reduced Floor Wear: Swivel casters distribute the load evenly while turning, which helps reduce the wear and tear on floors. This makes them suitable for use on delicate or sensitive surfaces, including hardwood floors, tile, and linoleum.

- Locking Mechanisms: Many swivel casters come with locking mechanisms that allow you to immobilize the caster’s swiveling function when needed. This feature adds versatility and ensures stability when required, such as when loading or unloading heavy equipment.

In summary, swivel casters offer exceptional maneuverability, versatility, and customization options, making them a popular choice for a wide array of applications across various industries. Their ability to rotate freely in any direction, combined with features like locking mechanisms and quiet operation, makes them a valuable component in materials handling and equipment mobility.

Swivel casters offer several advantages, including:

- Maneuverability: Swivel casters can rotate a full 360 degrees, allowing for easy movement in any direction. This exceptional maneuverability makes them well-suited for applications that require precise and flexible navigation.

- Tight Turns: The ability to make tight turns is a key advantage of swivel casters. This feature is particularly beneficial in confined spaces, crowded environments, and situations where equipment or loads need to be moved around obstacles.

- Versatility: Swivel casters come in various styles and configurations, offering a wide range of options to suit different needs. They are available with different wheel materials, load capacities, and brake systems, making them versatile and adaptable to various applications.

- Reduced Floor Wear: Swivel casters distribute the load evenly while turning, which reduces wear and tear on the floor. This is especially important when working on delicate or sensitive surfaces, as it helps protect the flooring from damage.

In summary, swivel casters are prized for their exceptional maneuverability, versatility, and customization options, which make them suitable for a wide range of applications. Their advantages include ease of movement, the ability to make tight turns, and their contribution to workplace ergonomics and safety. Whether in industrial settings, healthcare facilities, or everyday use, swivel casters are a valuable component in equipment mobility and materials handling.

Customizable aspects of swivel casters include:

- Wheel Material: Customers can choose from various wheel materials, such as rubber, polyurethane, nylon, steel, or special compounds. The selection depends on the application, including factors like load capacity, floor type, and resistance to chemicals or temperature extremes.

- Wheel Diameter: The size of the caster wheel can be customized to match the load requirements and the desired height for the equipment or furniture. Larger wheels typically provide better load distribution and easier rolling over obstacles.

- Wheel Bearing Type: Swivel casters can have different bearing types, including ball bearings, roller bearings, or precision bearings. The choice of bearing can affect the caster’s smoothness, durability, and load capacity.

- Mounting Options: Swivel casters are available with different mounting options, such as top plate mounts, stem mounts, or bolt hole mounts. The choice of mounting method depends on how the caster will attach to the equipment or furniture.

- Load Capacity: Swivel casters come in various load capacity ratings, and customers can select casters that match their specific load requirements. The load capacity is often a key consideration when customizing swivel casters.

- Swivel Locks and Brakes: Some swivel casters can be customized with locks or brakes to prevent unintended movement or swiveling. This is particularly important in applications where equipment or furniture needs to remain stationary or require precise positioning.

It’s essential to consult with the caster manufacturer or supplier to discuss the available customization options and select the features that best suit the specific requirements of your application.

There are several packaging solutions available for swivel casters, including:

- Bulk Packaging: Swivel casters are often packaged in bulk for large-scale buyers, manufacturers, or distributors. This packaging typically consists of casters bundled together in boxes or on pallets, making it efficient for those who require a significant quantity of casters.

- Individual Packaging: Swivel casters can also be individually packaged. Each caster is enclosed in its packaging, which often includes a box or blister pack. This option is suitable for retail sales, e-commerce, or when the casters need to be stored individually before use.

- Custom Kit Packaging: Some suppliers offer custom kit packaging, where swivel casters are packaged together with other components or accessories required for specific applications. This can include mounting hardware, locking mechanisms, or other related items.

- Reel or Roll Packaging: In some cases, swivel casters are packaged on reels or rolls, similar to how tape or rope is packaged. This packaging method is convenient for applications where casters need to be unrolled and installed quickly.

- Bulk Bags or Totes: Swivel casters can be packaged in bulk bags or totes, particularly when they are large or heavy. This packaging is common for industrial use and simplifies handling and transportation.

- Eco-Friendly Packaging: Some manufacturers are now offering eco-friendly packaging options. These packages may use recycled materials or minimal packaging to reduce waste and environmental impact.

The choice of packaging solution depends on factors such as the intended market, the volume of casters being sold, and the nature of the application. Whether you need large quantities for industrial use or retail-friendly packaging for consumer sales, there are various options to meet your specific packaging needs for swivel casters.