Features of locking casters include:

- Braking Capability: Locking casters are equipped with brakes that allow users to secure the caster wheels in place, preventing movement and ensuring stability. These brakes can be engaged or disengaged as needed.

- Swivel Locks: Swivel locking casters typically come with swivel locks that immobilize the swiveling action of the caster. This feature is particularly useful when you want to restrict the caster’s movement to a fixed direction.

- Wheel Locks: In addition to swivel locks, some locking casters also feature wheel locks. These locks prevent the wheel from rolling, even when the caster can still swivel. This is beneficial when you need to stop the rolling motion while maintaining the ability to change the direction.

- Pedal or Lever Actuation: Most locking casters feature a pedal or lever mechanism that can be easily operated by foot. Engaging the brake or lock is a simple process, allowing for quick and convenient control.

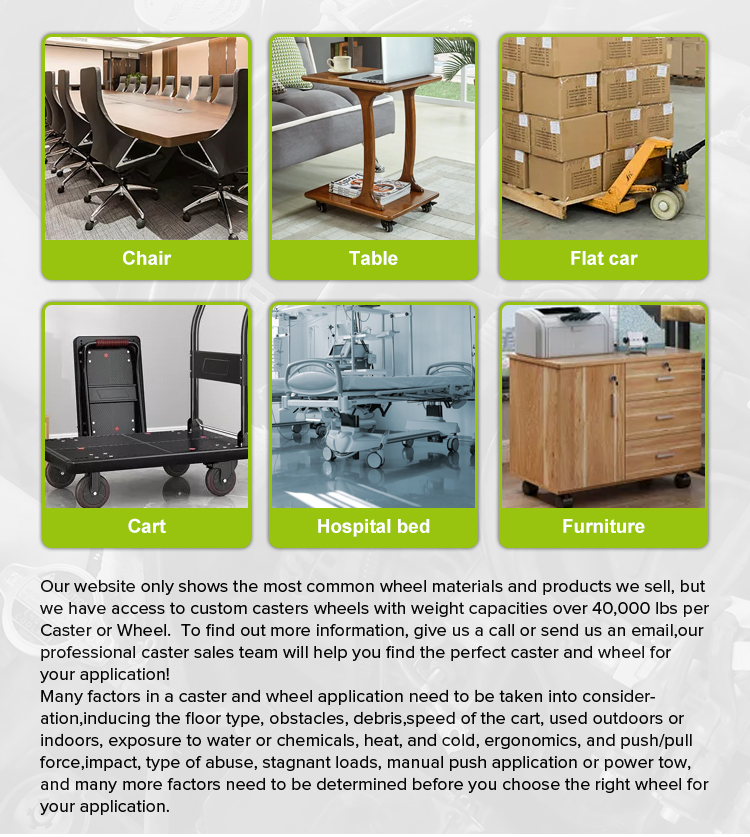

Overall, the features of locking casters enhance their usability in a wide range of applications by offering control, safety, and precision while maintaining mobility and adaptability when needed. These features make them an essential component in many industries and everyday scenarios.

Locking casters offer several advantages, including:

- Convenience: Engaging or disengaging the locks is typically straightforward and can be done quickly, often with a pedal or lever mechanism, providing users with convenience and ease of use.

- Controlled Mobility: Locking casters allow you to control the movement of equipment or furniture as needed. This is beneficial when you want to prevent unintended rolling, especially on inclined surfaces.

- Enhanced Stability for Delicate Tasks: In tasks that require stability and minimal vibration, locking casters can provide a steady base, making them suitable for applications like medical procedures or laboratory work.

- Heavy-Duty Options: There are heavy-duty locking casters designed to handle substantial loads while providing reliable braking and locking capabilities. These are commonly used in industrial applications.

In conclusion, locking casters offer a range of advantages, including stability, precision, versatility, and floor protection. These features make them an essential component in various industries and everyday scenarios where controlled mobility and safety are paramount.

Customizable aspects of locking casters include:

- Locking Mechanism Type: Some locking casters offer a choice between different types of locking mechanisms, such as a pedal brake, lever brake, or a hand-operated brake. The choice allows users to select the most convenient locking method for their application.

- Locking Strength: Users can often choose the strength of the locking mechanism, allowing for variations in how securely the caster is locked in place. This customization can be particularly useful when adjusting for different loads and equipment.

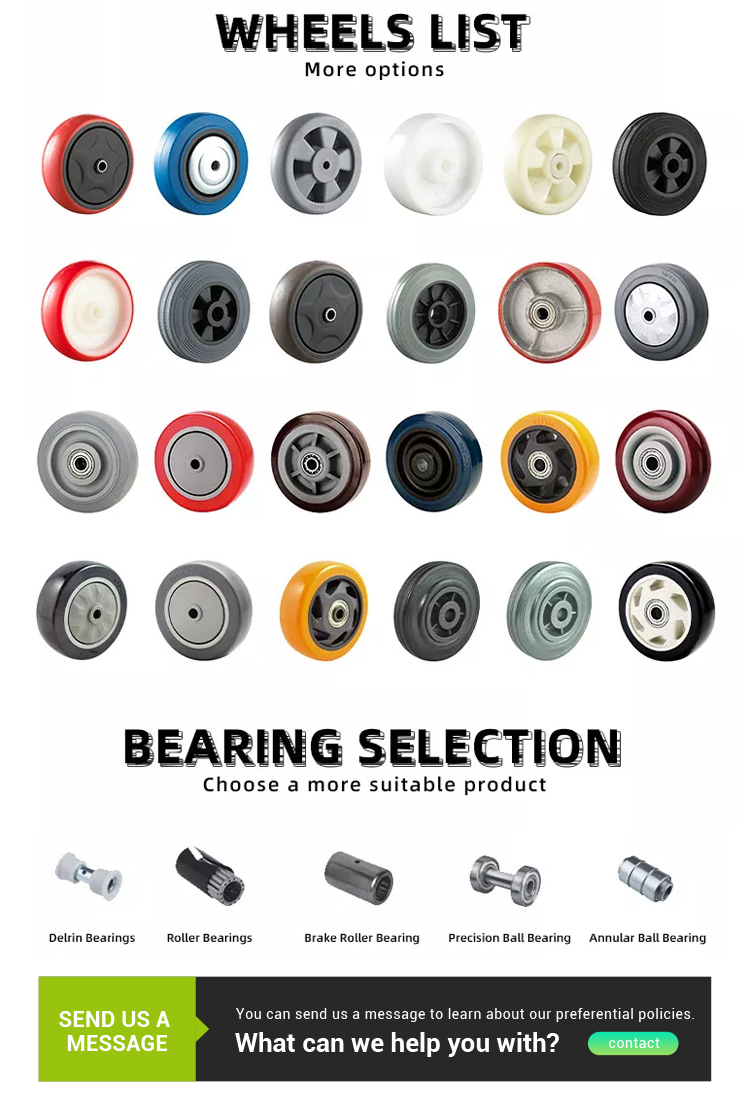

- Wheel Material: The type of wheel material can be customized to match the specific application. Options may include rubber, polyurethane, nylon, steel, or other specialized materials. The selection depends on factors like load capacity, floor type, and resistance to chemicals or temperature extremes.

- Wheel Diameter: Customization of the wheel diameter allows users to match the caster’s size to their equipment and load requirements. Larger wheels may provide better load distribution and ease of rolling over obstacles.

- Mounting Options: Locking casters come with different mounting options, such as top plate mounts, stem mounts, or bolt hole mounts. Users can select the mounting method that best fits their equipment or furniture.

- Locking Direction: In some cases, the direction in which the caster locks can be customized. Users can choose whether the caster locks in a swivel direction, rolling direction, or both, depending on their requirements.

The ability to customize locking casters ensures that users can tailor these components to their specific applications, whether in medical equipment, office furniture, industrial carts, or other scenarios where controlled mobility and safety are essential.

There are several packaging solutions available for locking casters, including:

- Individual Packaging: Each locking caster is packaged separately. This method is suitable for high-value or precision casters that need to be kept separate to prevent any potential damage during transport.

- Bulk Packaging: Locking casters are packaged together in bulk, typically in a single box or container. This approach is cost-effective and efficient when you have multiple casters to transport.

- Foam Inserts: Locking casters can be packaged with foam inserts that are custom-cut to fit each caster’s shape. Foam inserts provide a cushion and protect the casters from movement and potential damage.

- Plastic or Bubble Wrap: Some locking casters are individually wrapped in plastic or bubble wrap to protect them from scratches and minor impacts during shipping.

- Corrugated Boxes: Locking casters can be packaged in corrugated boxes that are designed to fit the casters snugly. These boxes provide structural support and protect the casters from external forces.

- Plastic Bags: Some locking casters are individually placed in plastic bags to shield them from dust and moisture. This is especially useful when casters are shipped internationally or in challenging environments.

The choice of packaging solution often depends on the caster type, quantity, shipping method, and the level of protection required. Regardless of the packaging method, the goal is to ensure that locking casters arrive at their destination in optimal condition, ready for use in their intended applications.